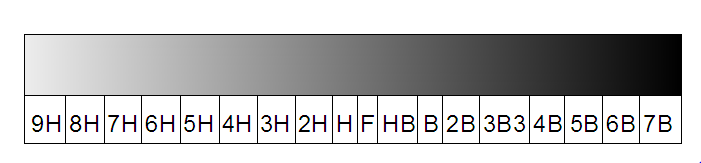

All pencils are not the same. You cannot produce quality engineering drawings with ordinary pencils and lead. Pencil lead is made from graphite and is available in various hardness grades. The hardness of the lead is controlled by changing the clay content in the graphite. Technical lead hardness is specified using the H-B (hardness/blackness) scale. 9H is the hardest, and 7B is the softest. Engineering drawings can be constructed with two or three hardness grades (4H, F and B).

A hard pencil is used to lay out light lines that are not intended to be seen by the reader. These are called construction lines. Construction lines are used to precisely position various features on the print. When using a hard lead, keep in mind that the goal is an extremely light line. Use only very light pressure. A good pencil grade for construction lines is 4H.

Generally, a drawing requires two line weights: thin and thick. For these two a grade F (thin) and a grade B (thick) are used. These leads would ideally be held in a type of pencil known as a lead holder.

Leadholders make mechanical drawing more productive. By rolling the pencil, they can be used for extended periods of time without sharpening.

Lead holders were the tool of choice for people who had to do a lot of mechanical drawing. They hold a large diameter (usually 2mm) piece of lead and can be used for extended periods of time without sharpening. A skilled draftsperson would roll the pencil as they drew to keep the point sharp.

For lettering, where the pencil rolling technique cannot be employed, a mechanical pencil is used. Either hardness grade F or HB lead is adequate for lettering. The easily obtained lead diameter of .5 is best for lettering.

Recent Comments