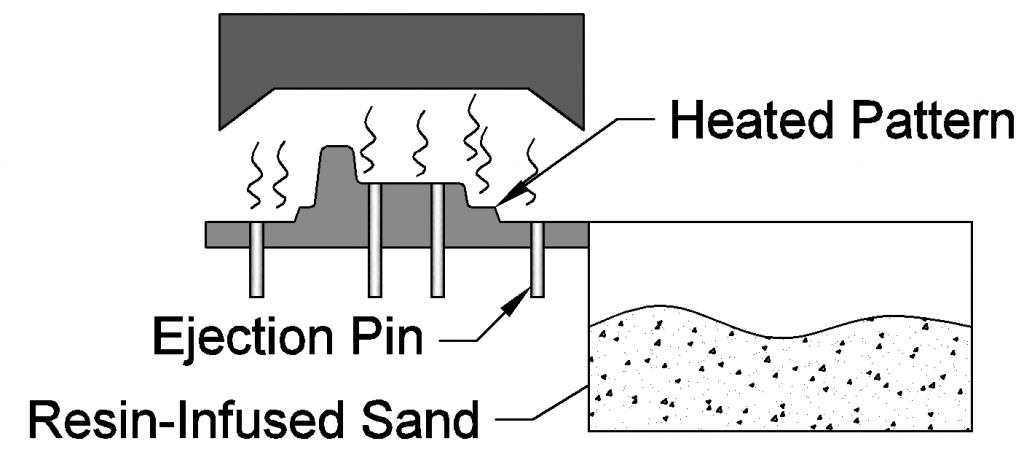

In shell mold casting, a heated pattern is coated with a resin-infused sand. This resin hardens and forms a “shell” around the pattern. These pattern halves are bonded together and encased in sand to form a mold.

Process

First, the metal pattern is heated.

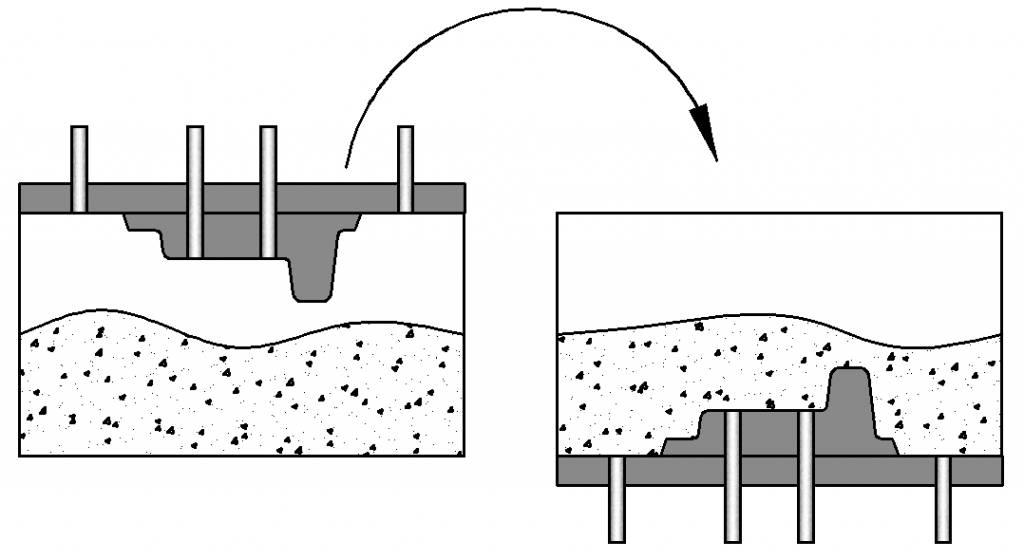

The pattern is closed over the sand container and inverted.

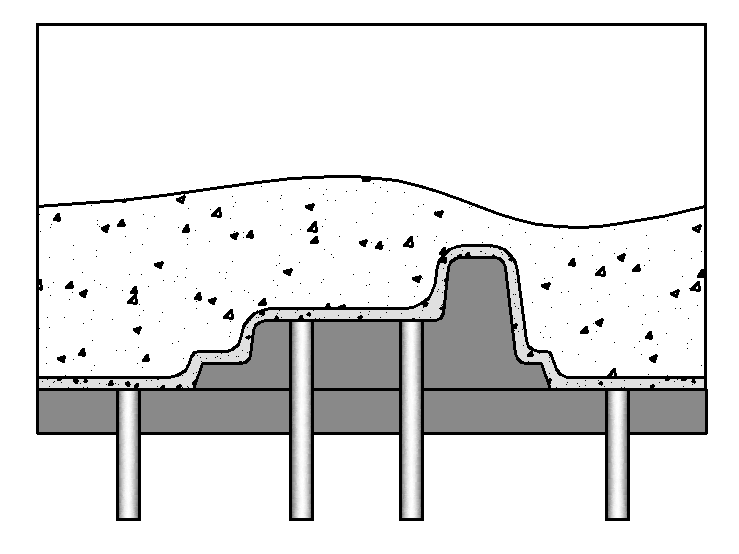

The resin close to the pattern melts and fuses the sand.

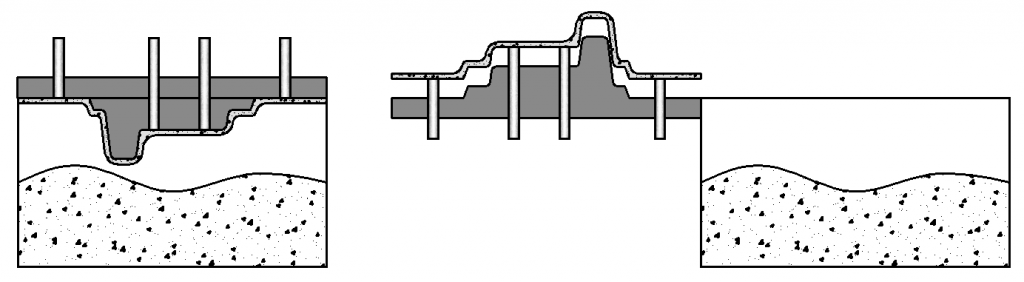

The shell is allowed to cool and is removed from the pattern with the ejection pins.

The shell mold halves have a long shelf life and can be stored until needed.

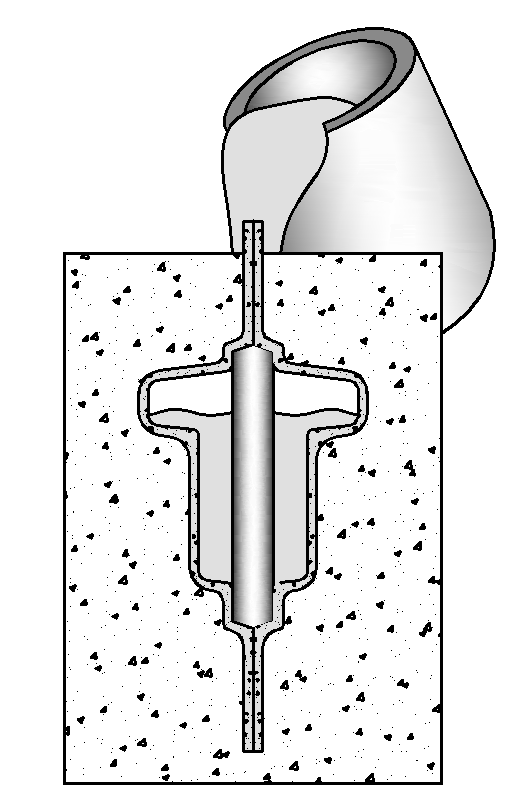

The shell mold halves are bonded together and encased in sand and filled with molten metal. Cores can be added as necessary. Shell molds may also serve as cores in other casting processes.

References

Engineers, Susha Founders &. SUSHA Shell Moulding Machine | Dumpbox Moulding. YouTube, 29 Dec. 2019, https://www.youtube.com/watch?v=UnJZy_0MGrw.

Recent Comments