Investment casting is the modern embodiment of the very ancient lost wax casting.

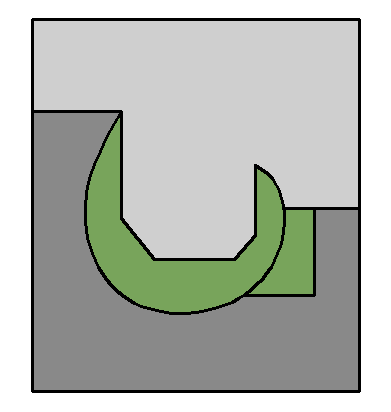

The process starts by making a wax model of the desired component. Here the wax part is injection molded.

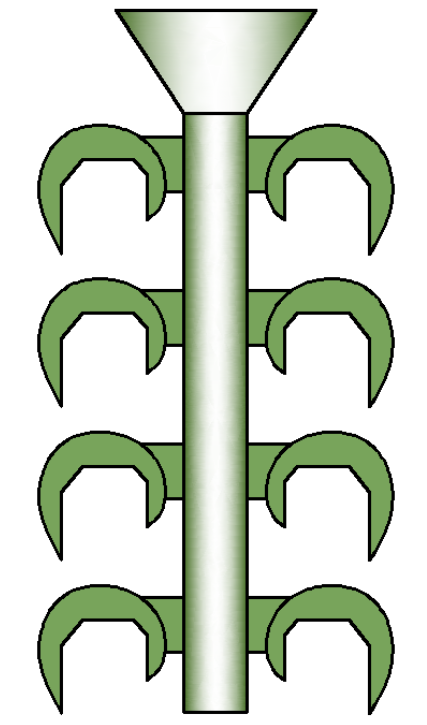

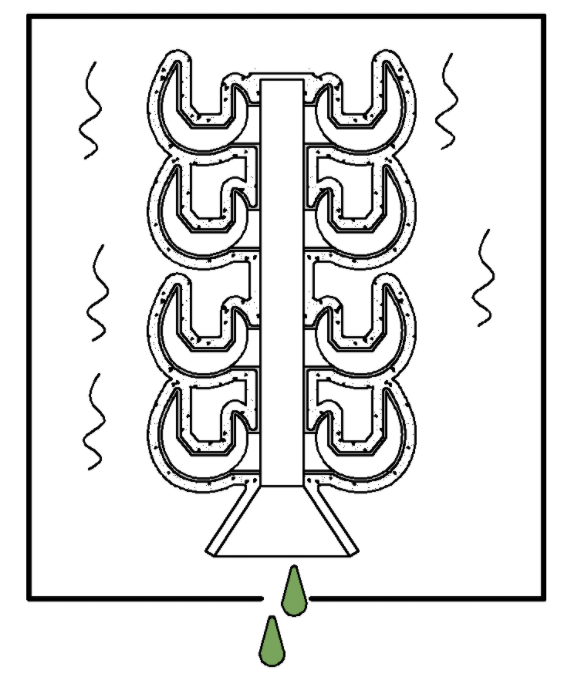

Wax patterns are assembled onto a common wax sprue

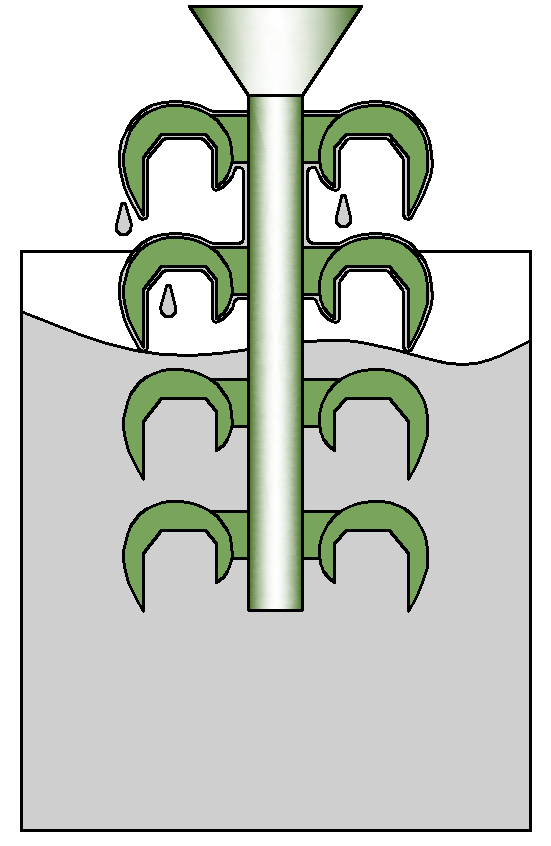

The assembled tree is then coated with a refractory slurry.

The slurry is then covered with a dry refractory powder. This is repeated many times.

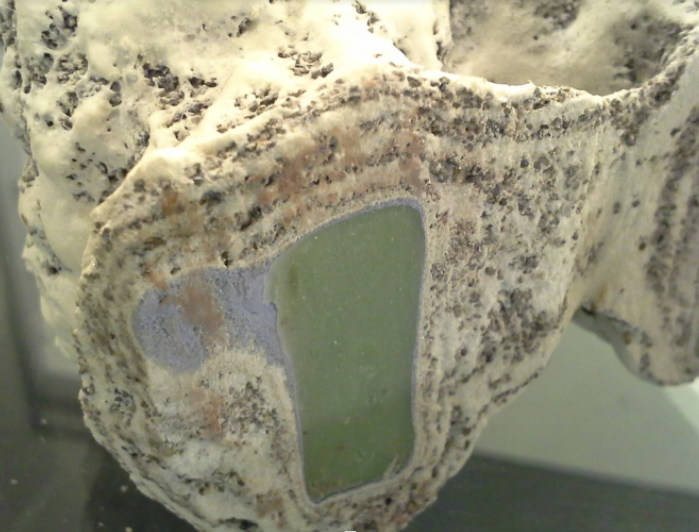

An investment of refractory material is built up.

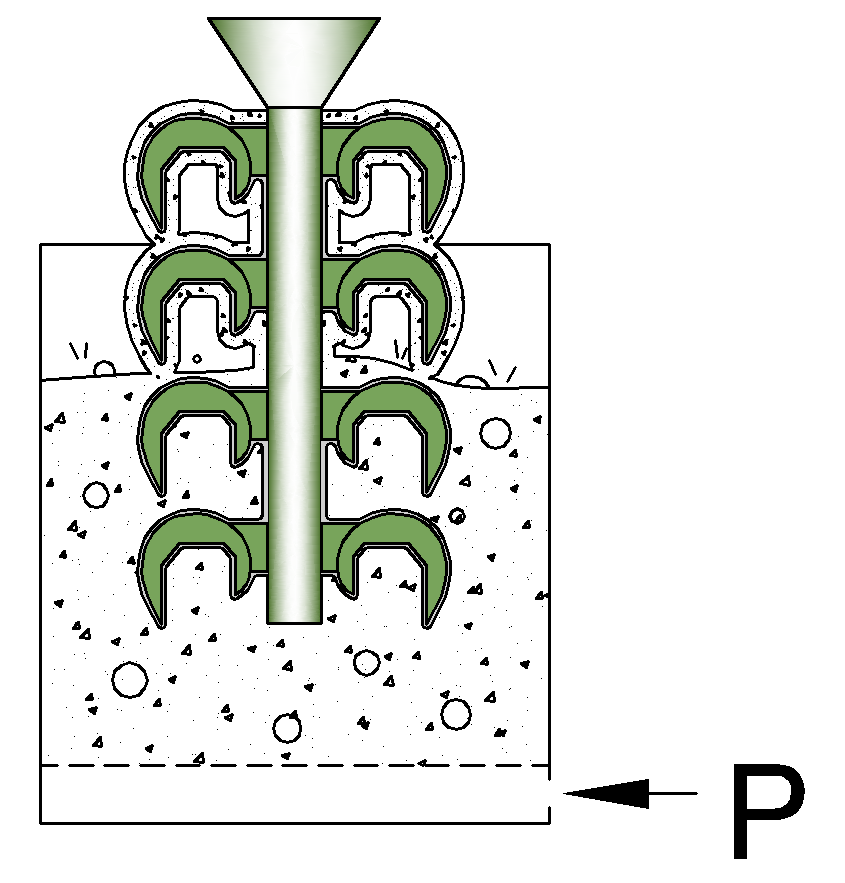

The wax is melted out, and the ceramic investment is fired to form a strong mold.

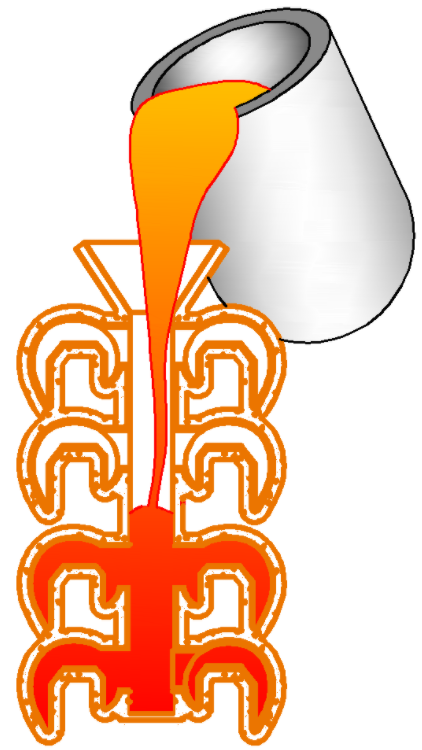

The mold is then heated further and poured.

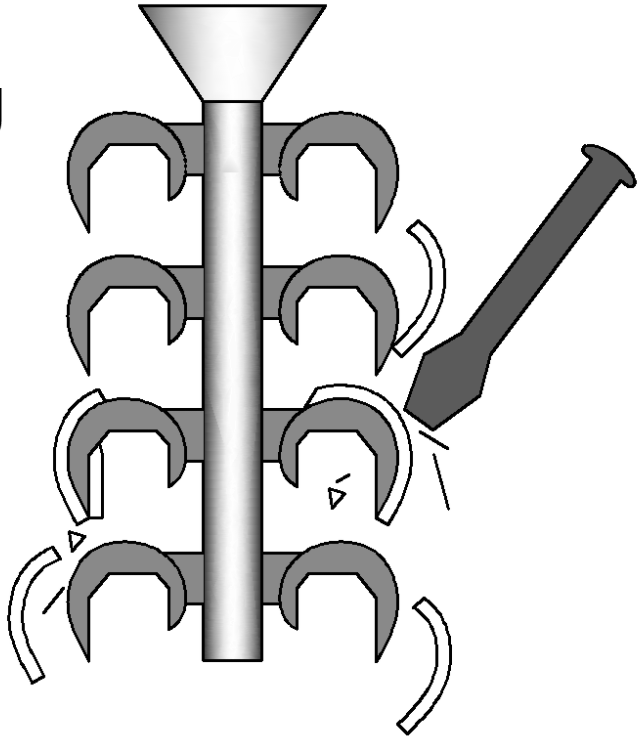

The investment is then removed mechanically.

The individual parts are then separated and finished.

Recent Comments