- Introduction

- Face Milling

- Peripheral Milling

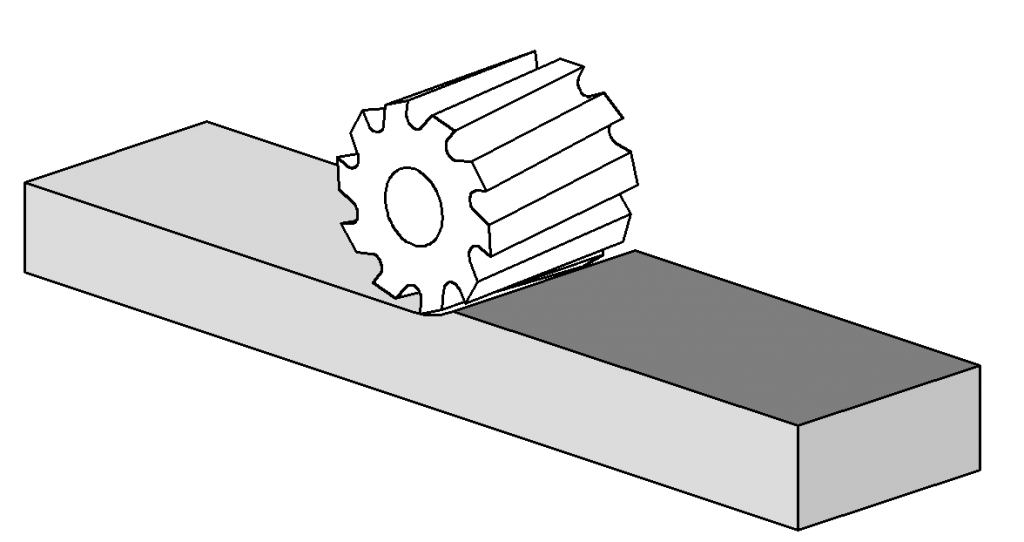

- Slab Milling

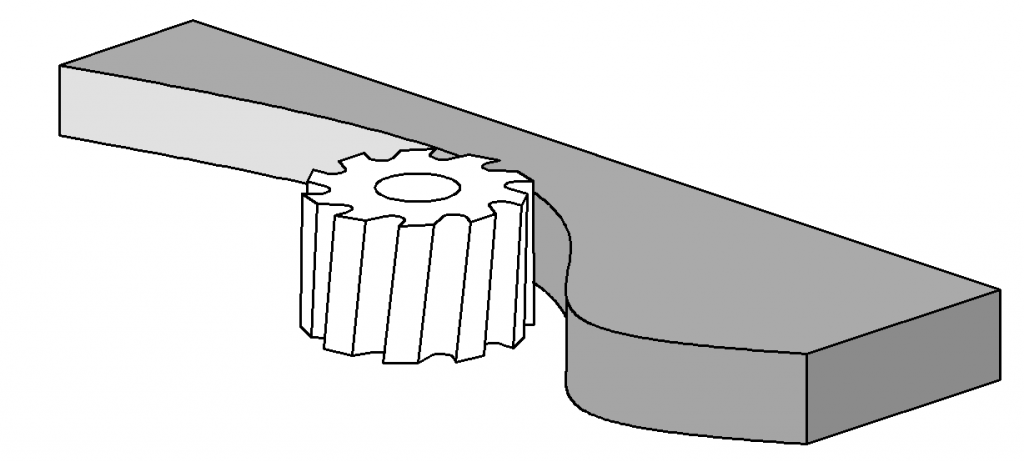

- Profile Milling

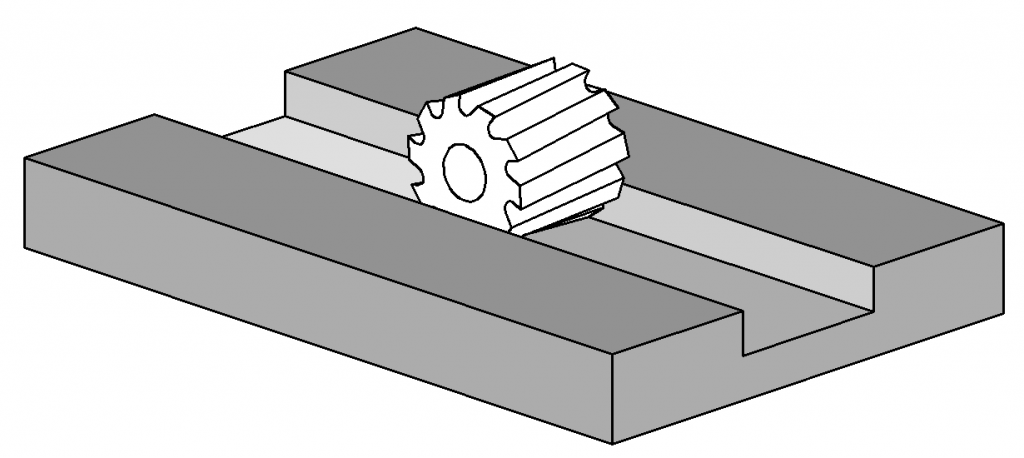

- Slotting

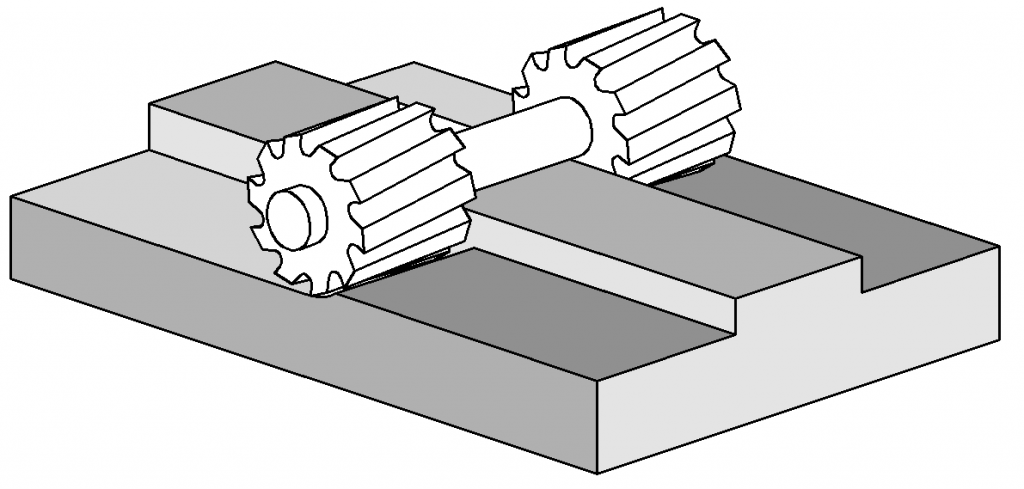

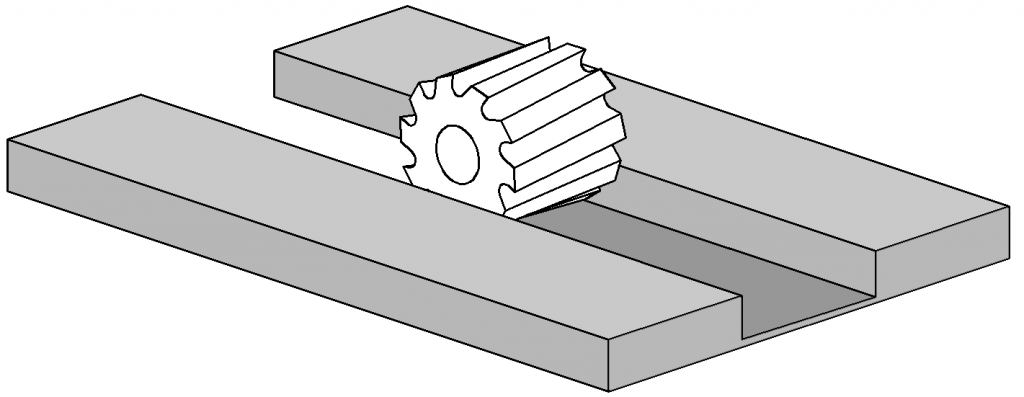

- Straddle Milling

- Slitting

- End Milling

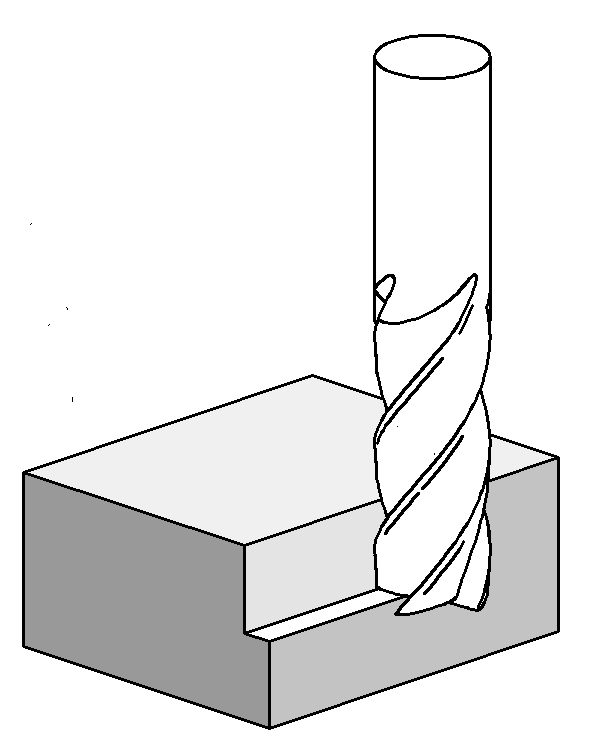

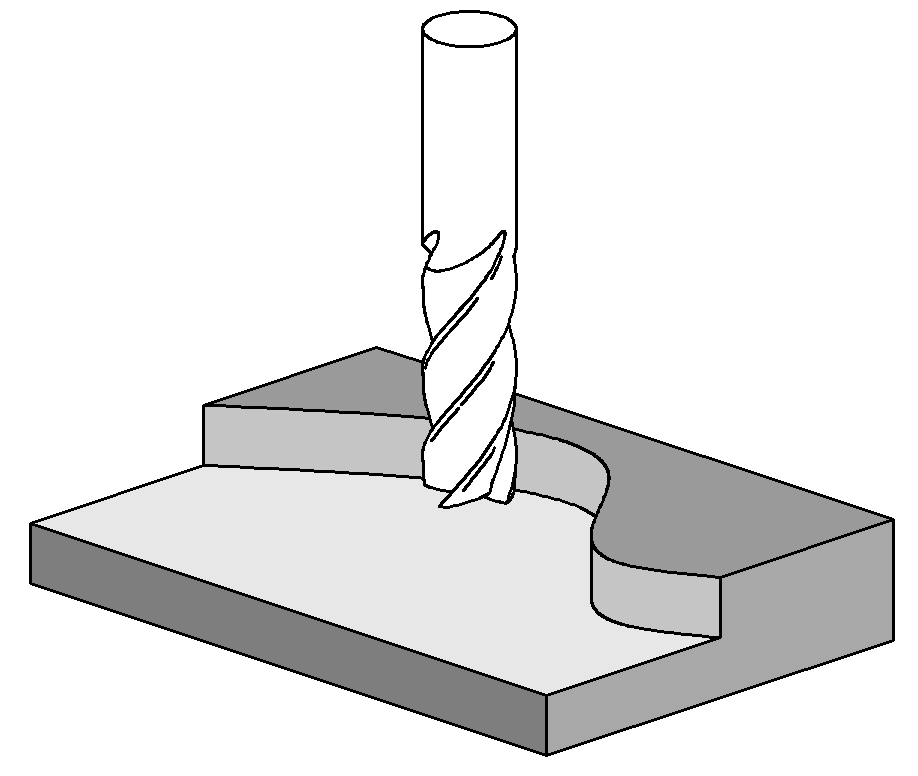

- Shoulder Milling

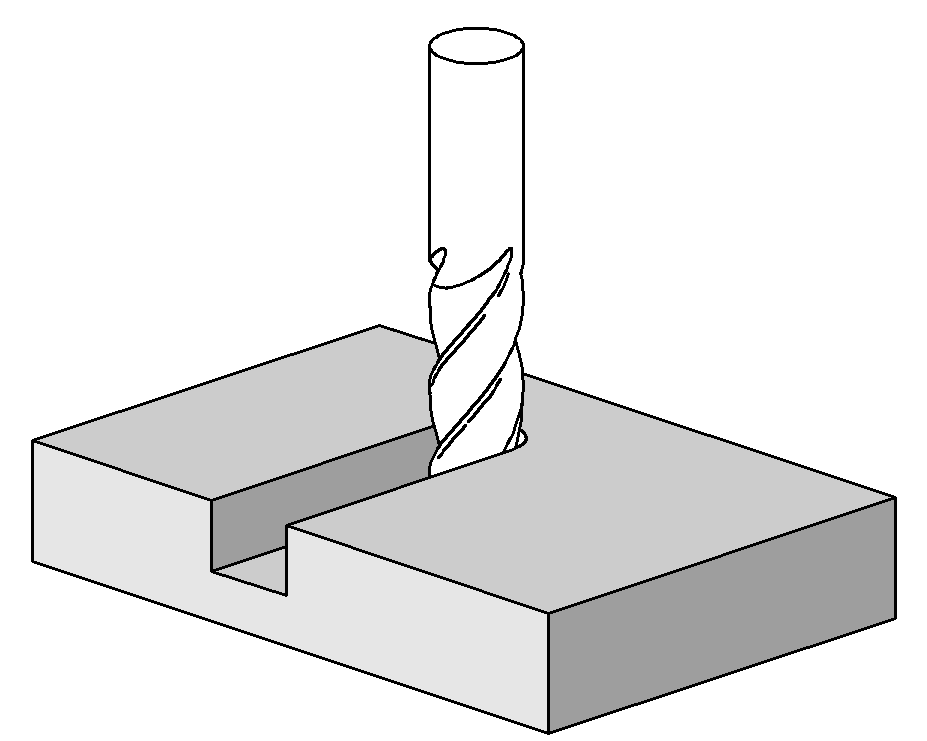

- Slotting

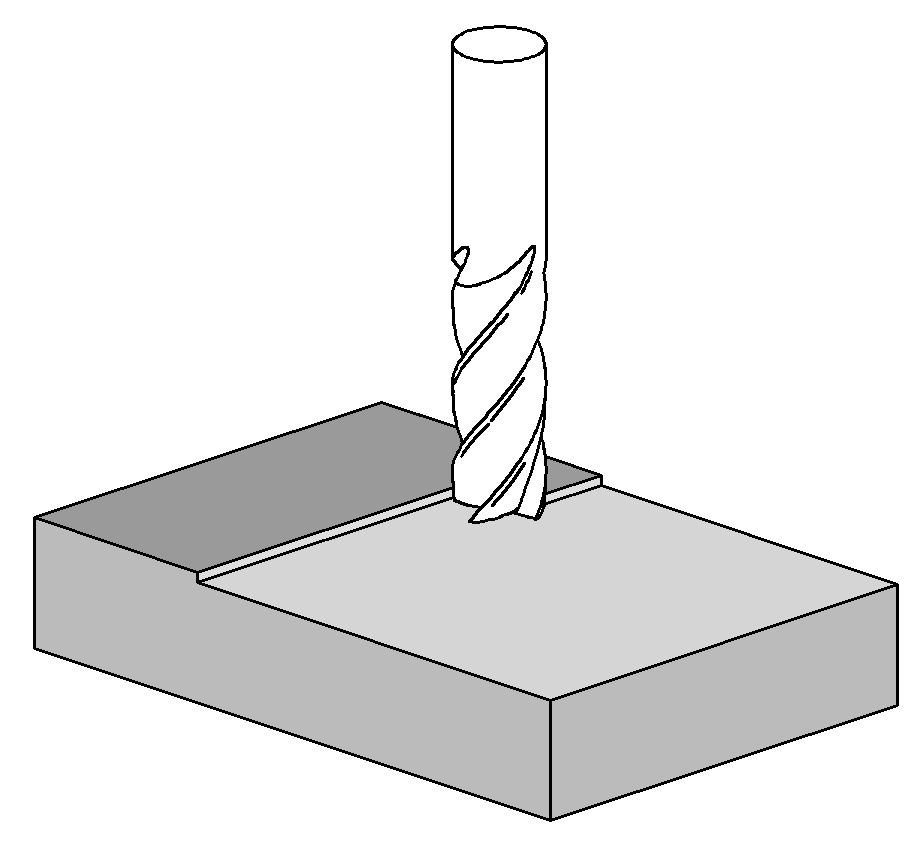

- Facing

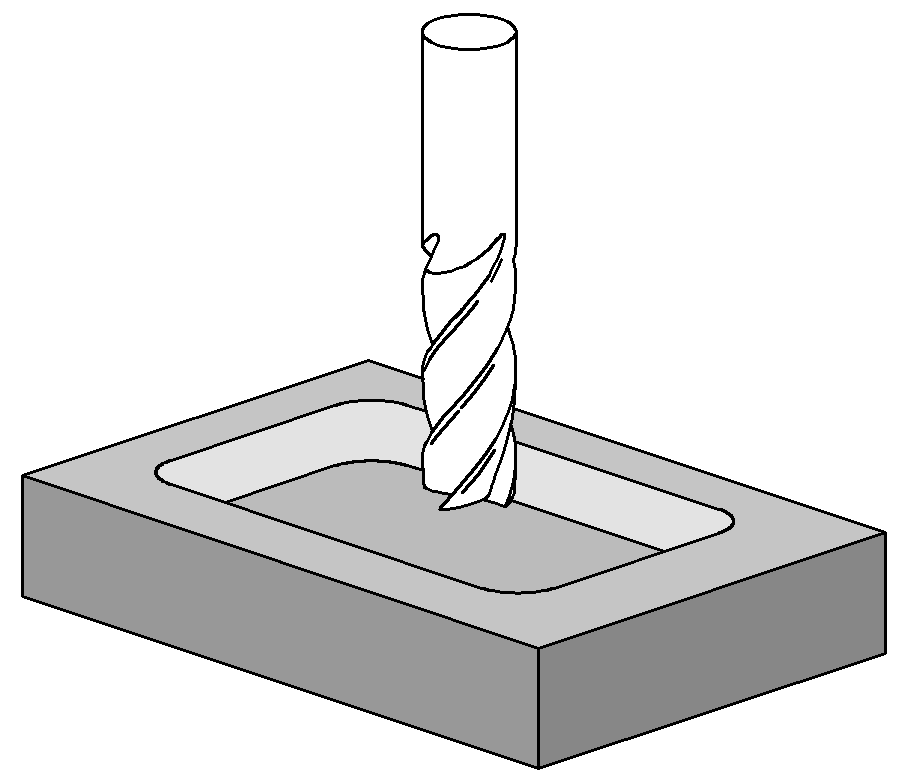

- Pocketing

- Profiling

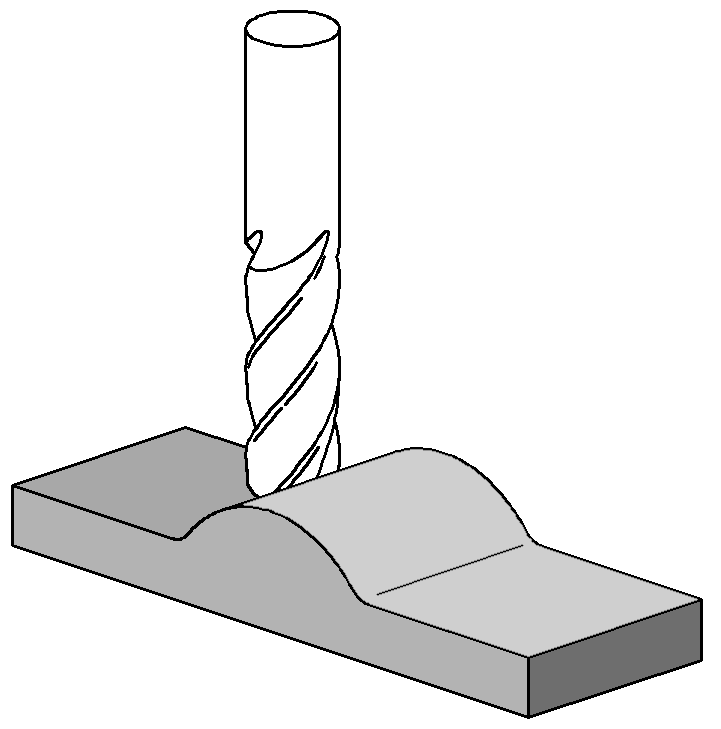

- Contouring

Introduction

Milling machines can be used to perform a wide variety of machining operations. While milling machines can be used to perform holemaking and specialized machining operations, they usually perform tasks that fall into one of these three categories: face milling, peripheral milling, and end milling. Let’s look at each of these in a little more detail.

Face Milling

In face milling the cutter is oriented perpendicular to the surface being cut. Face milling is used to create a broad, flat surface on a workpiece. Face mills often have a large diameter and many cutting teeth, however face milling can be done with a tool called a “fly cutter” that has a single cutting surface.

Peripheral Milling

Peripheral milling is performed with the circumference of a round tool. Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations.

Slab milling is similar to face milling in that it removes material to make the surface of a workpiece flat and or to reduce the overall thickness of a part.

Profile milling creates an exterior contour with a desired shape.

Slot milling or slotting produces rectangular or rounded channels in a workpiece.

Straddle milling may use two or more cutters on the same arbor to create a rectangular pad of a desired width. Using two or more cutters simultaneously in this way is known as gang milling. Gang milling can be used to create more complex shapes, such as v-ways and cooling fins.

Slitting is similar to slotting but cuts completely through the workpiece.

End Milling

End milling is probably the most common class of operations performed on milling machines. End mills are cylindrical cutters that normally have two or more cutting edges on both the periphery and end of the tool.

End milling operations include side milling, slotting, facing, or partial facing, pocketing, profiling, and contouring.

Shoulder Milling

Side milling is probably the most common end milling operation. In side milling the tool is engaged both axially and radially. The amount of axial engagement is known as the “stepover” and is often specified in percent of tool diameter.

Slotting

Slotting fully engages the end mill in the workpiece, and creates a slot with a rectangular or rounded profile depending on the end mill shape.

Facing or partial facing is done more efficiently with other types of tools such as fly cutters or face mills, but it can be done with an end mill.

Pocketing can create round holes, or it can create rectangular or other shaped pockets. Notice that whenever interior corners are created with an end mill they will have a radius at least as large as half the end mill’s diameter.

Profiling is done on the perimeter of a workpiece and can produce nearly any shape that has interior radii at least as large as that of the cutter.

Finally contour milling. Often done with a rounded tool called a ball end mill, contour milling can produce shapes with a three dimensional contour. Contouring can be used to produce tooling such as injection molds and forming dies.

Because profile milling and contour milling require control in more than one axis at a time, they are generally done on CNC mills today, but were historically done with tracing mills that reproduced contours and profiles from a master pattern.

Recent Comments