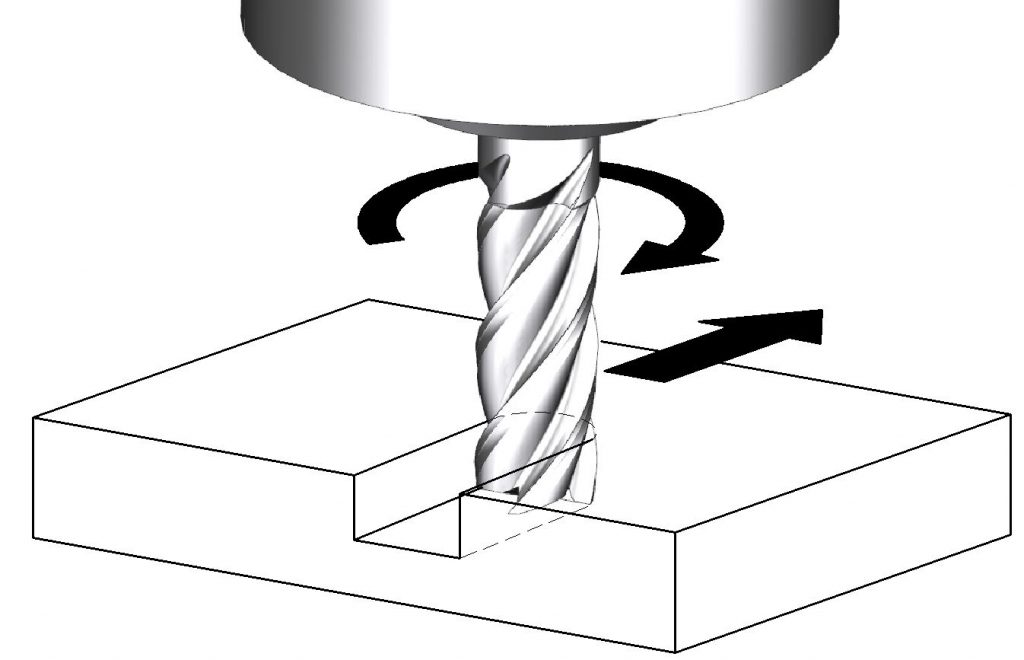

Milling machines are machine tools that use a rotating cutter to perform different kinds of material removal operations in metals, plastics, and other materials.

Milling machines can be manual machines, or they can be CNC (or computer numerically controlled).

In some milling machines the spindle is oriented vertically. These machines are called vertical milling machines. The most common configuration of a manual vertical milling machine is the knee mill. Knee mills have a large support member called the “knee” that supports the workpiece and moves vertically, along the spindle axis.

Vertical CNC milling machines that are equipped with automatic tool changers and other automation options are commonly referred to as “vertical machining centers” or VMC’s.

Another category of milling machines have the spindle oriented horizontally. These are called horizontal mills. In many applications the horizontal orientation of the spindle helps chips fall down and out of the way of the cutting tool.

Horizontal machines are often built with a more rigid frame than vertical machines, and CNC Horizontal mills are often used with workholding fixtures called “tombstones” that allow many parts to be fixtured and machined at the same time.

Horizontal machines with toolchangers and other automation options are called “horizontal machining centers” or HMC’s.

Some milling machines are hybrids between a milling machine and a lathe. These machines, called “mill-turn” or “turning mill” machines can make cuts in the same way a milling machine does, but they can also rotate the workpiece at high speed as in a lathe.

Manual milling machines have a number of movable joints that allow them to be put into various configurations. However, these machines are usually limited to three primary axes of motion. These are referred to the X, Y and Z axes.

Motion in the z axis is parallel to the axis of the spindle. The X axis is the motion of the table, and is usually parallel to the floor, and the Y axis is motion perpendicular to the X and Z axes. Here it is the motion of the saddle in and out of the machine.

On CNC machines, there may be three, four, five or even more axes of motion.

Again, the motion of the Z axis is the easiest to find. Whether it is a vertical or horizontal milling machine, the Z axis is almost always the axis parallel to the spindle. The X axis is usually the longest, and it is often parallel to the floor. The Y axis is perpendicular to X and Z axes.

Rotary axes are often designated A, B, and C. With A being rotation around the X axis, B being rotation around the Y axis, and C being rotation around the Z axis.

Recent Comments