Calipers

Calipers were originally used to make measurements of opposing parallel planar surfaces or internal or external diameters of parts. For discussion of this type of caliper, see: Calipers – Simple (Non-Graduated).

Modern slide calipers are more versatile and can measure step heights, hole depths, and other surfaces as well.

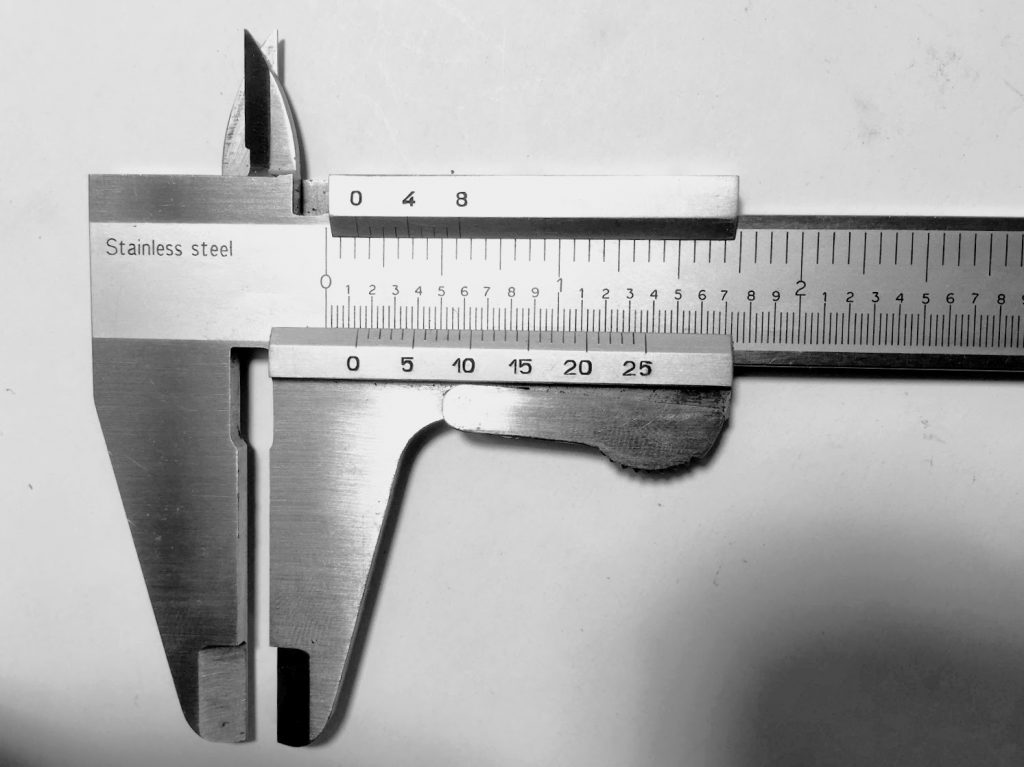

Slide Calipers

Slide calipers are generally graduated calipers used for making measurements directly. Slide calipers can make internal, external, step and depth measurements. To determine which surfaces can be used to make measurements, close the caliper completely. The flush surfaces on the closed caliper can be used to take measurements.

The most common types are:

- Vernier Calipers

- Dial Calipers

- Digital Calipers

Vernier Caliper

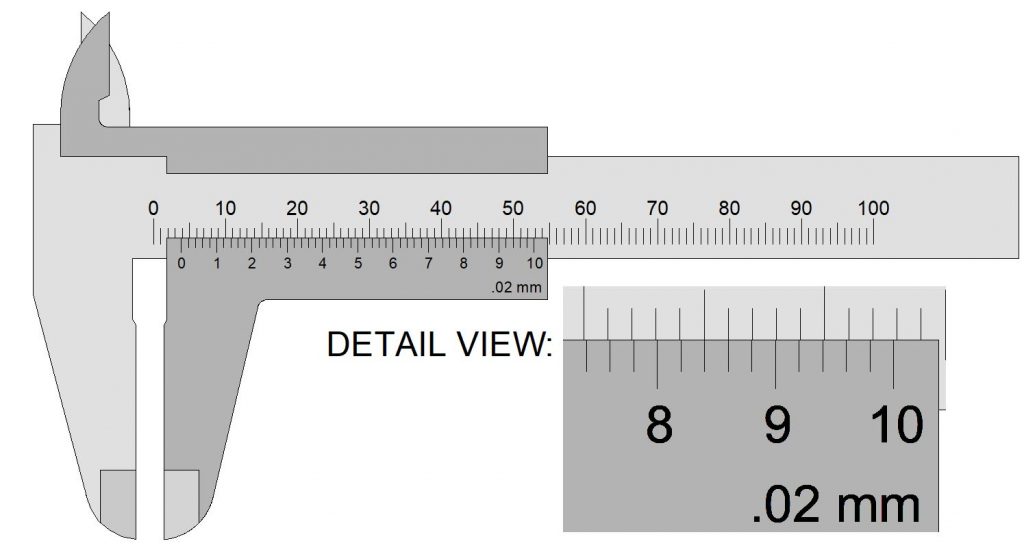

Vernier calipers have two scales, a main scale and a vernier scale. On the metric vernier caliper shown below, the reading on the main scale is 3mm. When the reading from the vernier scale (

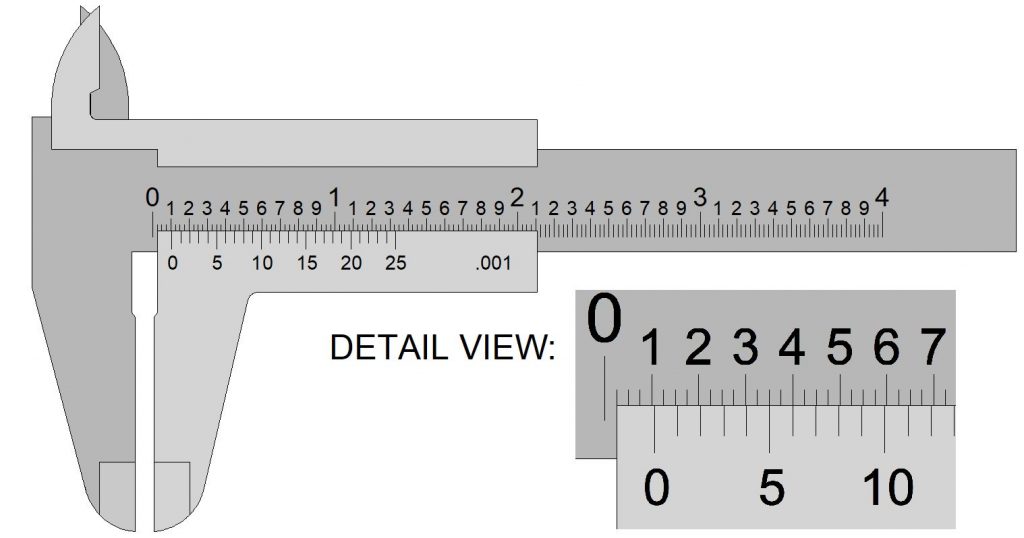

Inch vernier calipers usually have a main scale that is graduated to the nearest .025 inch (as shown below). The vernier scale allows reading to the nearest .001 inch.

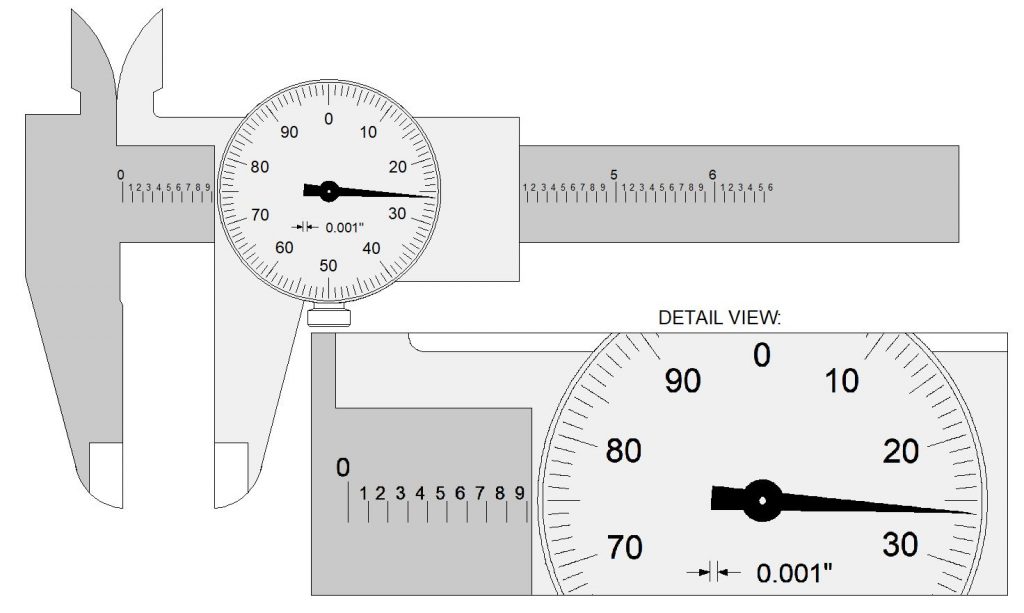

Dial Caliper

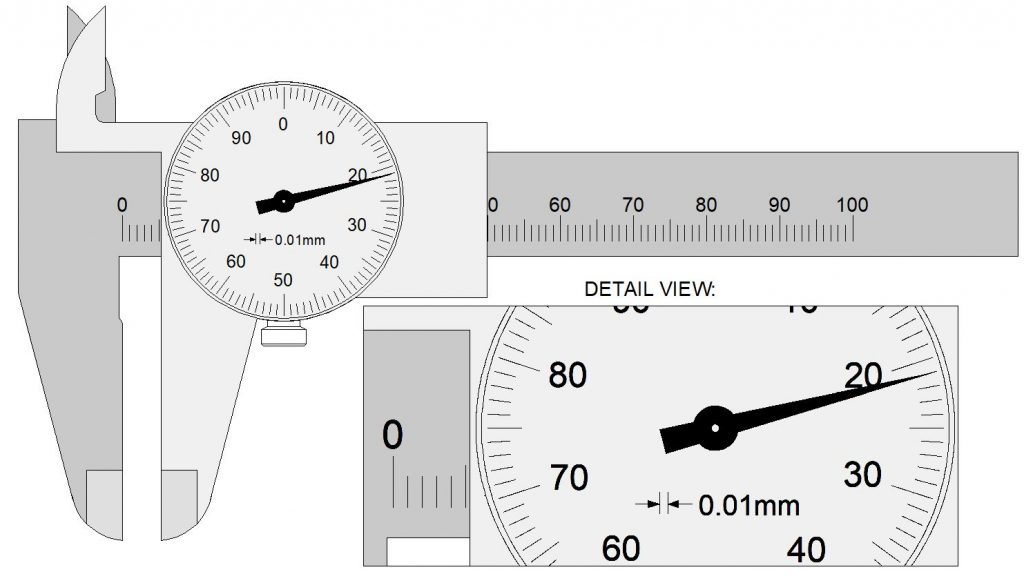

Dial calipers typically work on a rack and pinion gear system, and are available in a variety of resolutions.

Metric dial calipers are often graduated as shown below, with the main scale in millimeters and the dial giving the first and second decimal places.

Inch dial calipers often have a main scale resolution of .1 inch and the hundredths and thousandths places on the dial. Some dial calipers have one revolution per .1 inch and others have one half revolution per .1 inch.

Digital

Height Gages

Recent Comments