- Straight Turning

- Taper Turning

- Facing

- Contour Turning

- Form Turning

- Parting

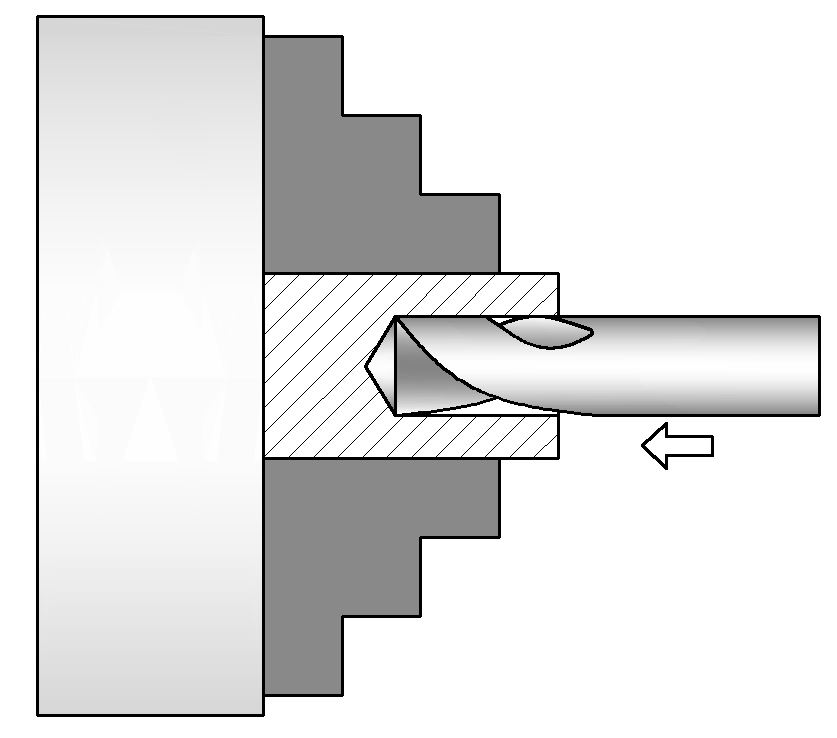

- Drilling

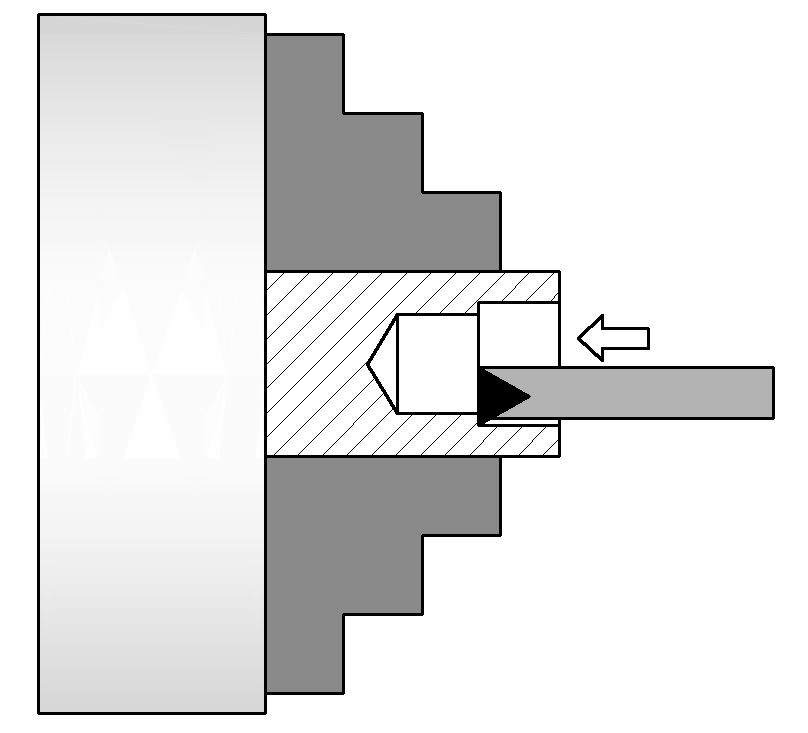

- Boring

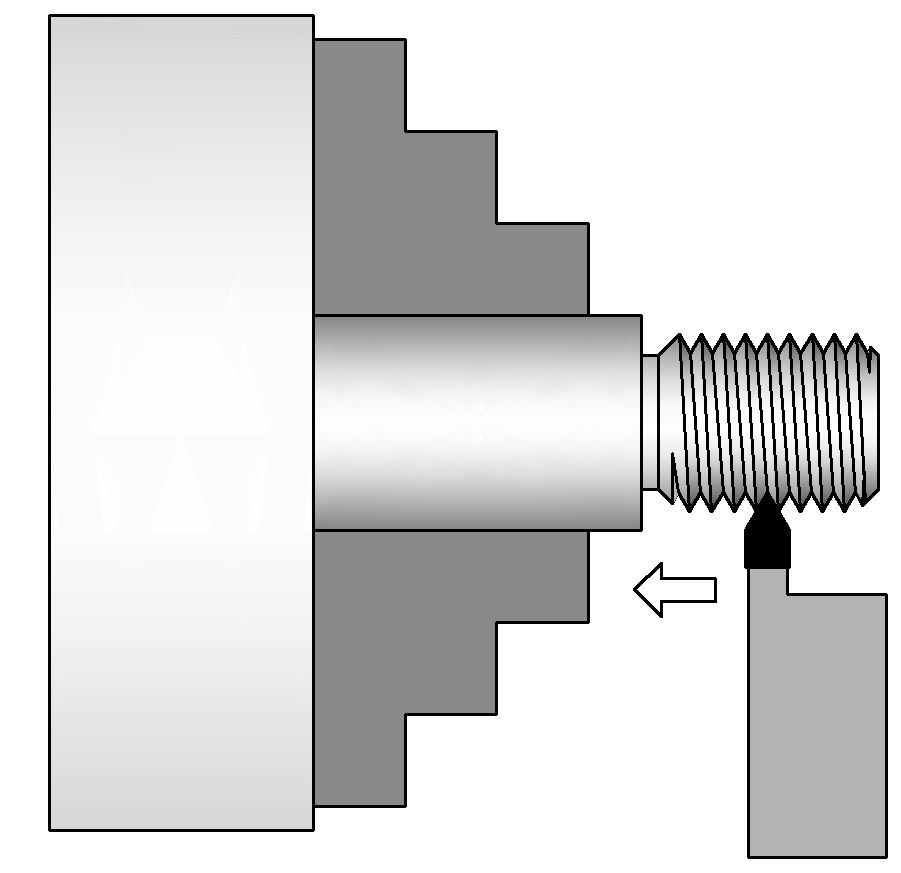

- External Threading

- Internal Threading

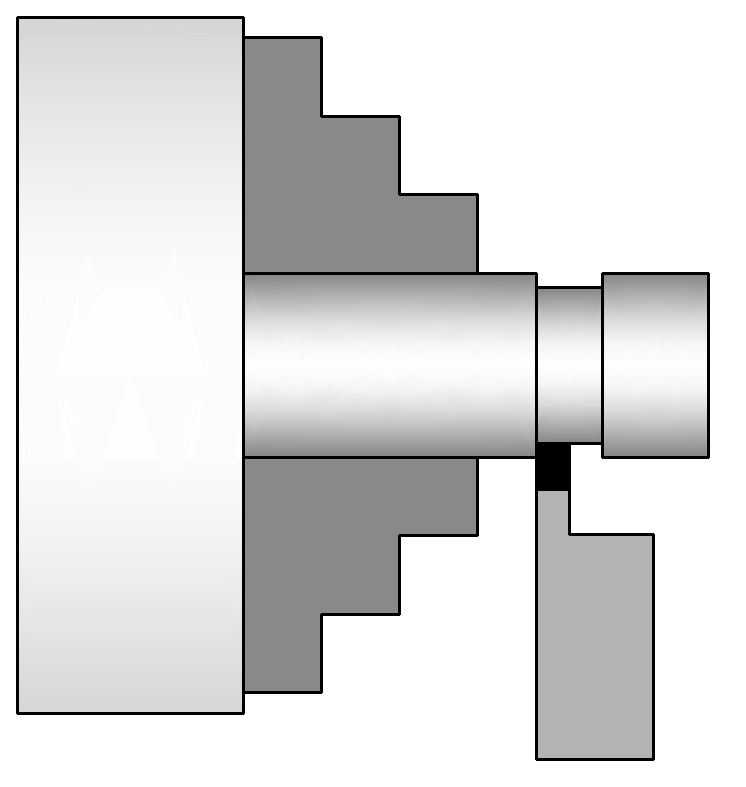

- Grooving or Necking

- Knurling

Straight Turning

Can be right or left handed. Right handed turning is when the cutter moves from right to left.

Taper Turning

Taper turning can be done using a taper attachment, the compound rest, or by offsetting the tailstock. Taper turning can also be done on a CNC lathe.

Facing

Facing is working on the flat face of the workpiece.

Contour Turning

Contour turning is usually performed on a CNC lathe. Historically, tracers were used to create irregular shapes on a lathe.

Form Turning

Form turning is used to impart an irregular shape on a workpiece using a specially ground tool.

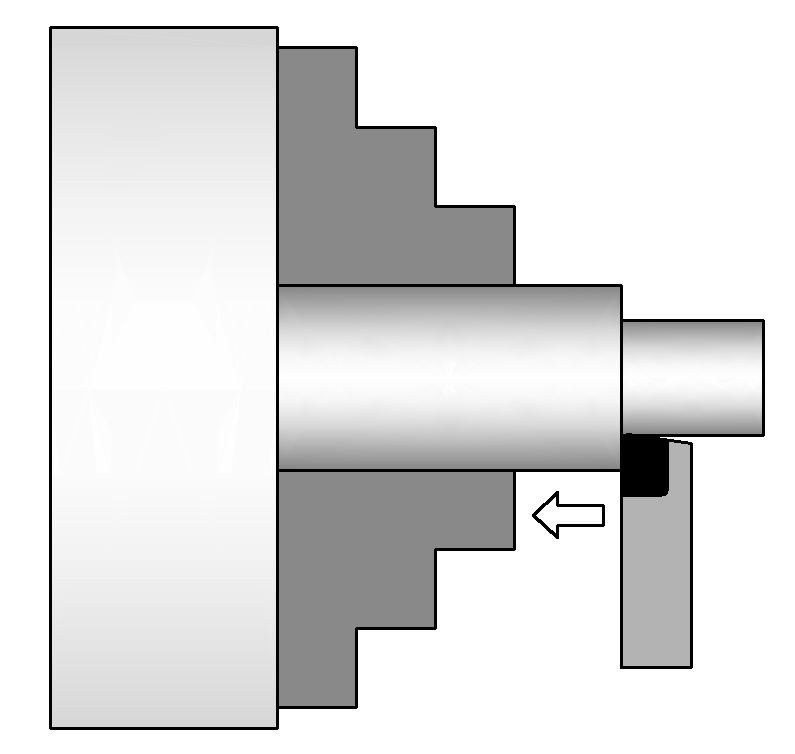

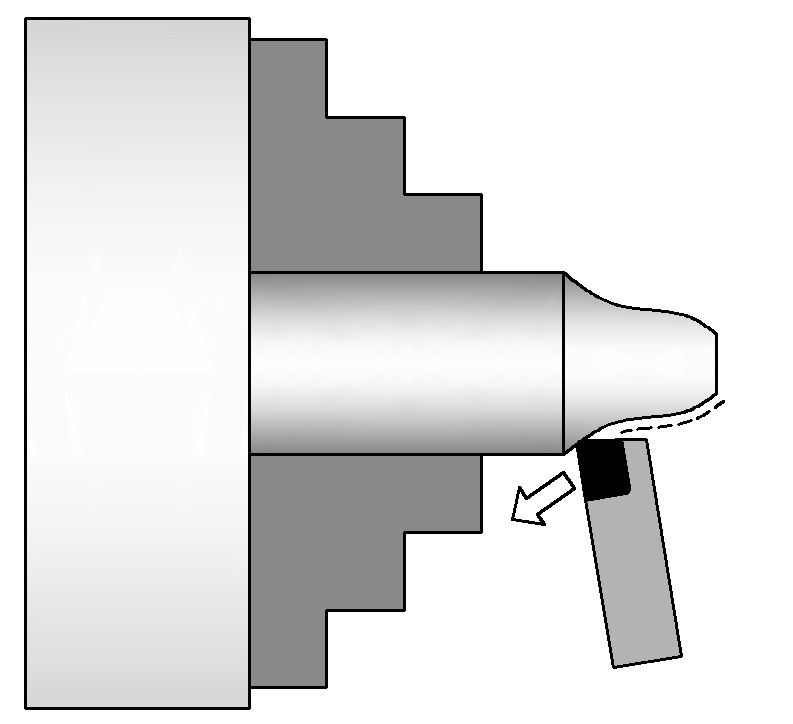

Parting

Parting is used to cut off a workpiece. A thin parting tool is used.

Drilling

See also: Drilling and Hole Making

Drilling can be accomplished by holding the drill bit in the tailstock and rotating the workpiece.

Boring

Boring removes material from a previously drilled hole. It can enlarge the hole and improve the roundness and surface finish.

External Threading

External threading creates male screw threads on a workpiece.

Internal Threading

Internal threading creates female threads inside a hole in a workpiece.

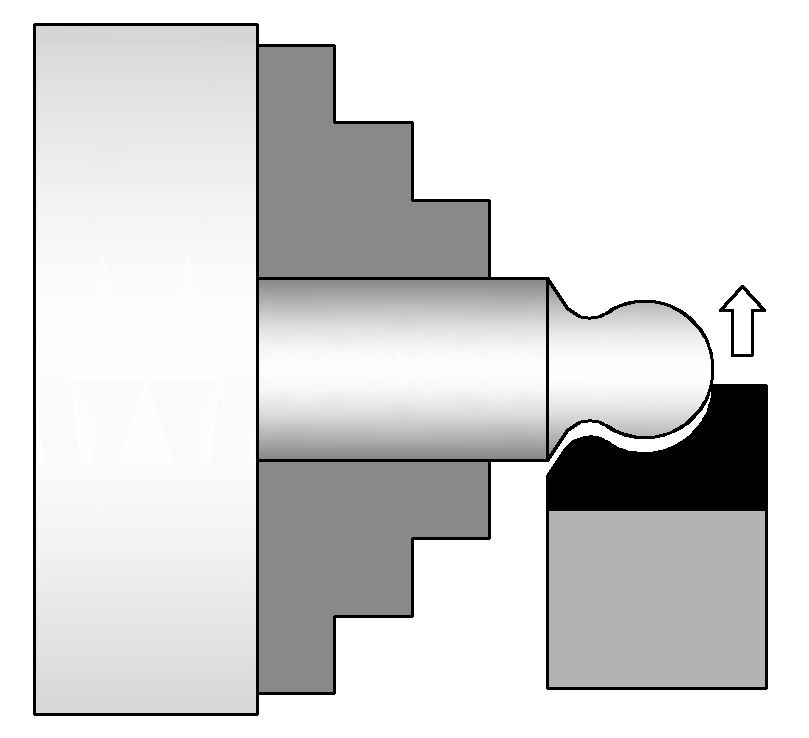

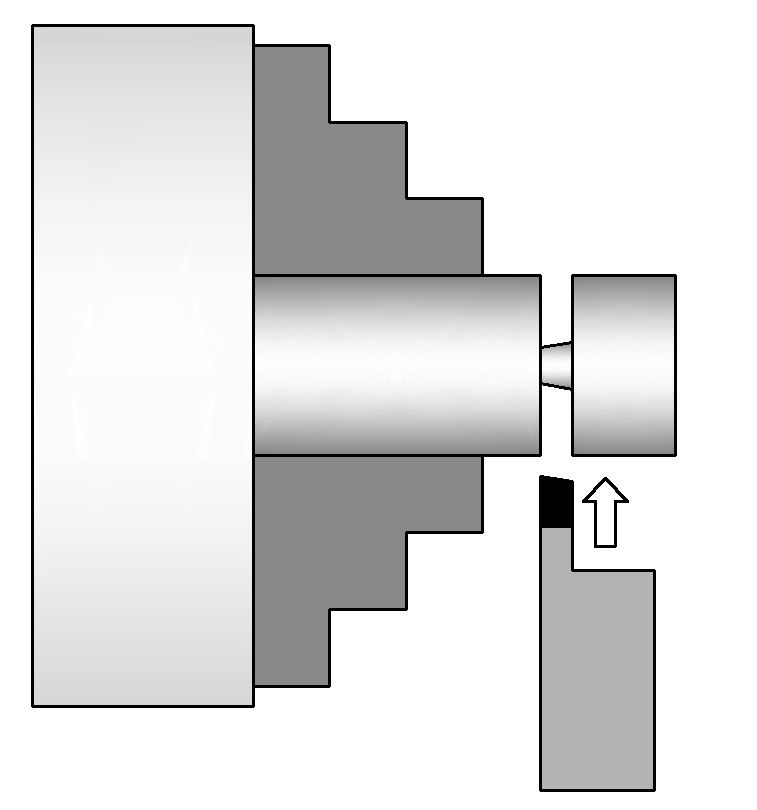

Grooving or Necking

Grooving can create grooves for items such as retaining rings or glands for o-rings. Grooving can be internal or external.

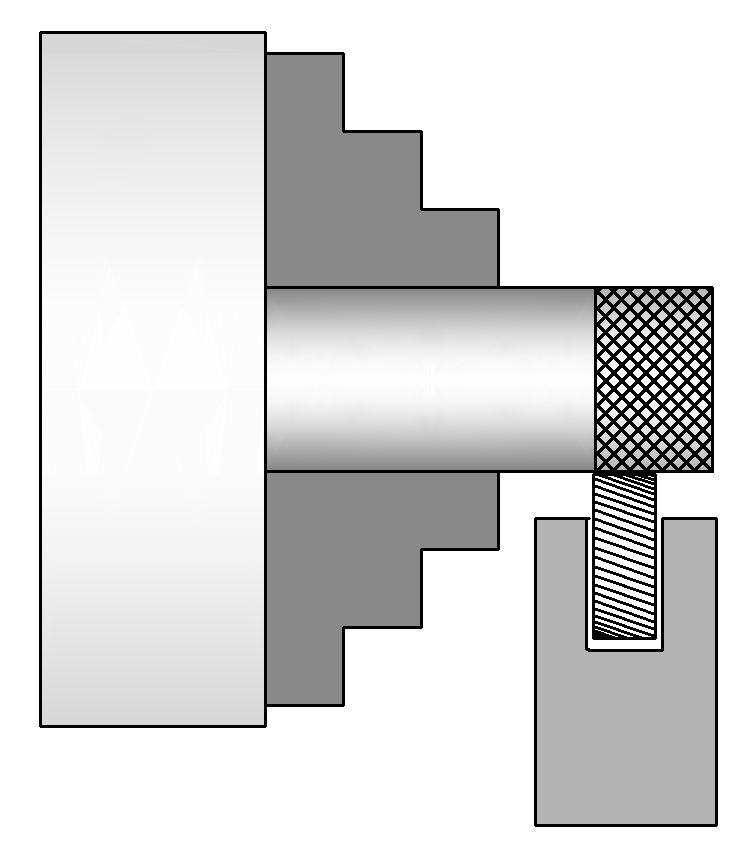

Knurling

Knurling forms a pattern on a workpiece. Knurling can be decorative or functional. Knurling increases the effective diameter of the workpiece.

Recent Comments