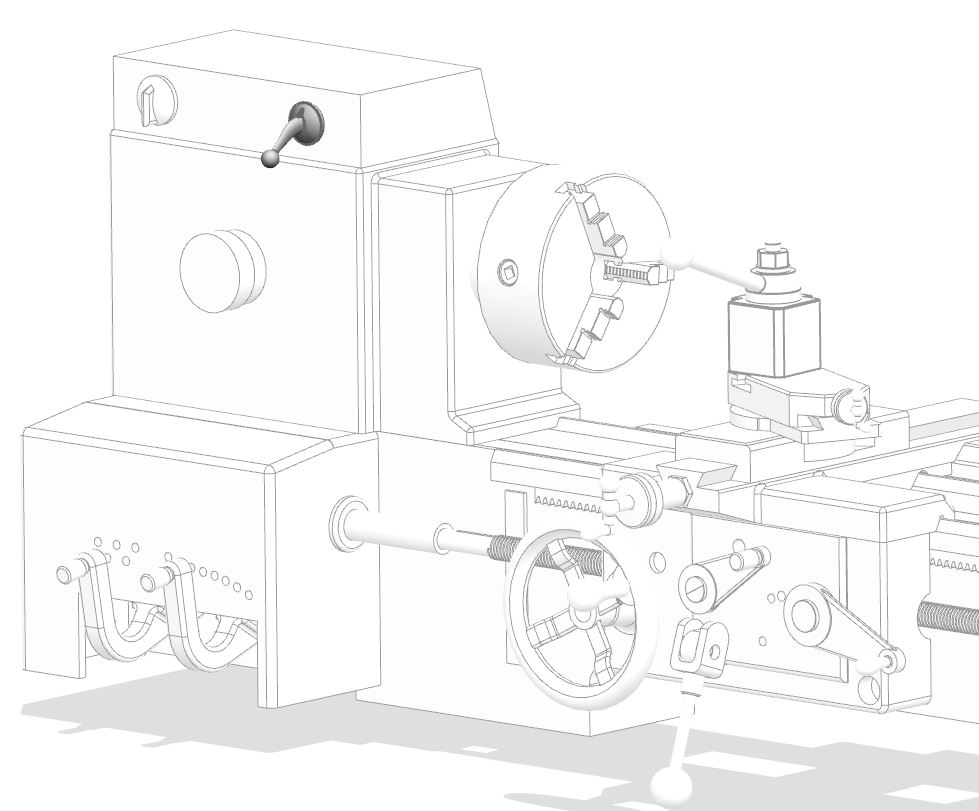

- Headstock

- Spindle & Spindle Nose

- Chuck

- Spindle Power Switch

- Spindle Speed Control

- Powerfeed Gear Levers

- Powerfeed Direction Selector

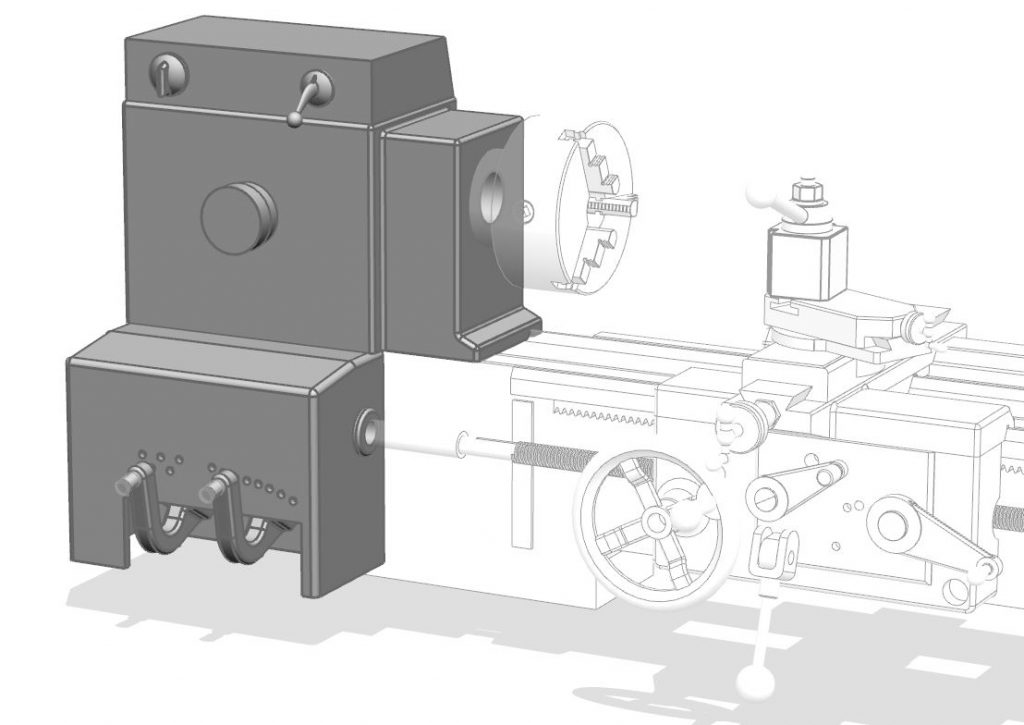

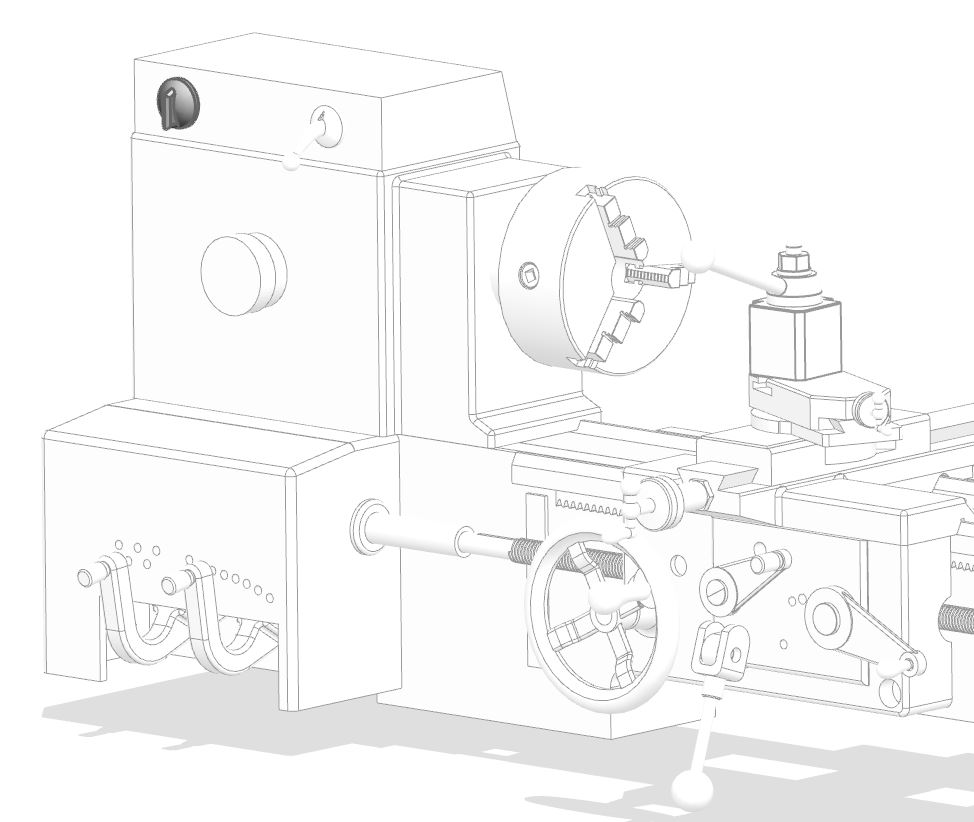

Headstock

The headstock contains the motor, spindle, gears and controls for the rest of the lathe.

The headstock contains the motor, spindle, gears and controls for the rest of the lathe.

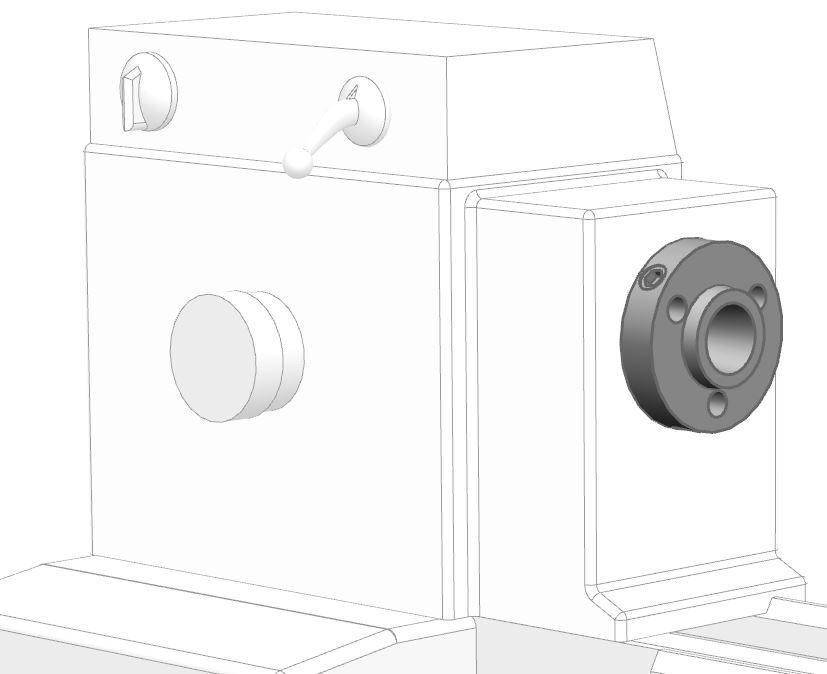

Spindle & Spindle Nose

The spindle is the primary rotating element of the lathe (see: video).

The spindle nose is the attachment point for a variety of workholding fixtures. There are a variety of spindle standards and sizes.

See: Tools-n-gizmos.com

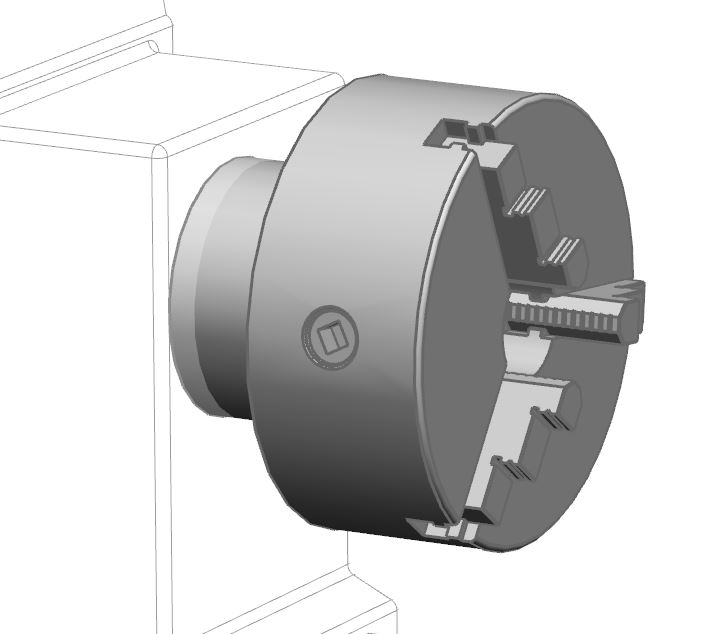

Chuck

Chucks are a convenient way to hold workpieces the lathe. A three-jaw scroll chuck is shown here installed on the spindle nose. For other lathe workholding devices see: Lathe Workholding.

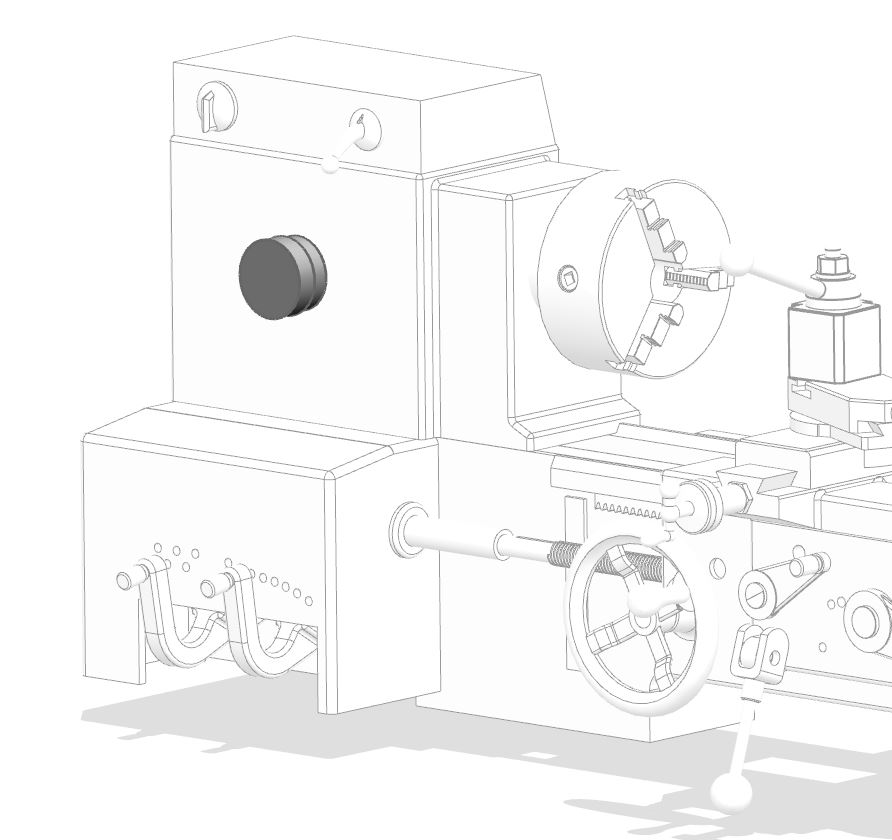

Power Switch

On some lathes the power to turn the spindle on is located on the headstock. On other lathes it may be a lever on the apron of the carriage. Obviously, CNC lathe spindles are controlled by the sofware, with the main power switch usually being mounted on the control panel.

Spindle Speed Control

On many lathes the spindle speed is controlled by selecting a combination of gear ratios. On others, the spindle may be controlled mechanically by devices such as continuously variable speed units or by electrically by variable frequency drives.

Powerfeed Gear Levers

The gear ratio for the leadscrew and feed rod may be set by changing the combinations of the powerfeed gear levers. This is done in a variety of ways on different lathes.

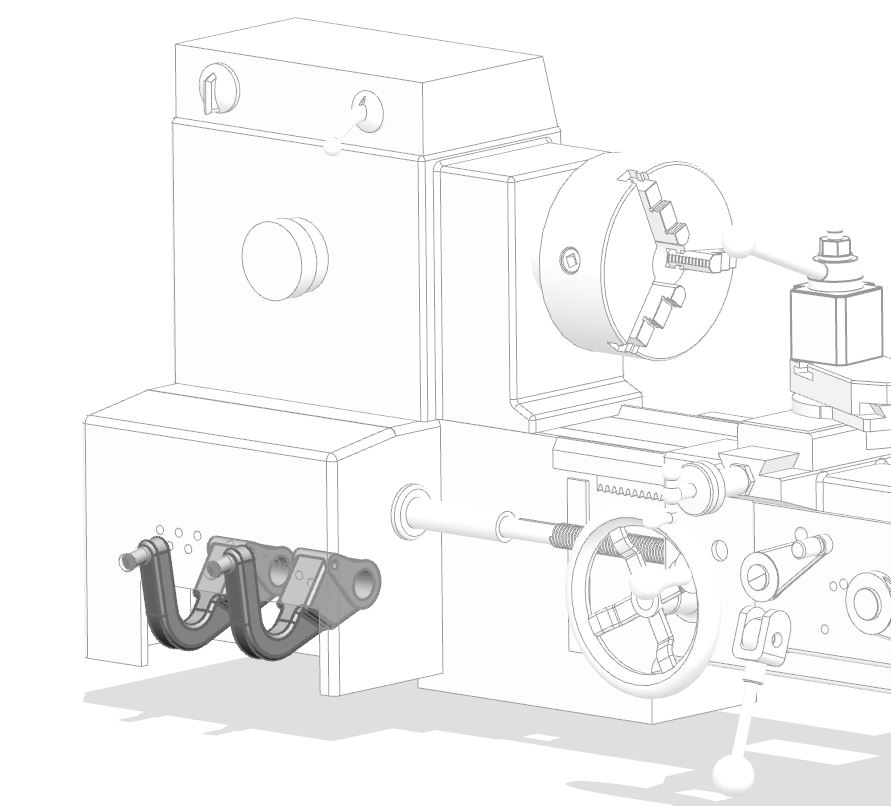

Powerfeed Direction Selector

The direction of rotation of the feed rod or the leadscrew can be reversed by changing the position of the powerfeed direction selector.

Recent Comments