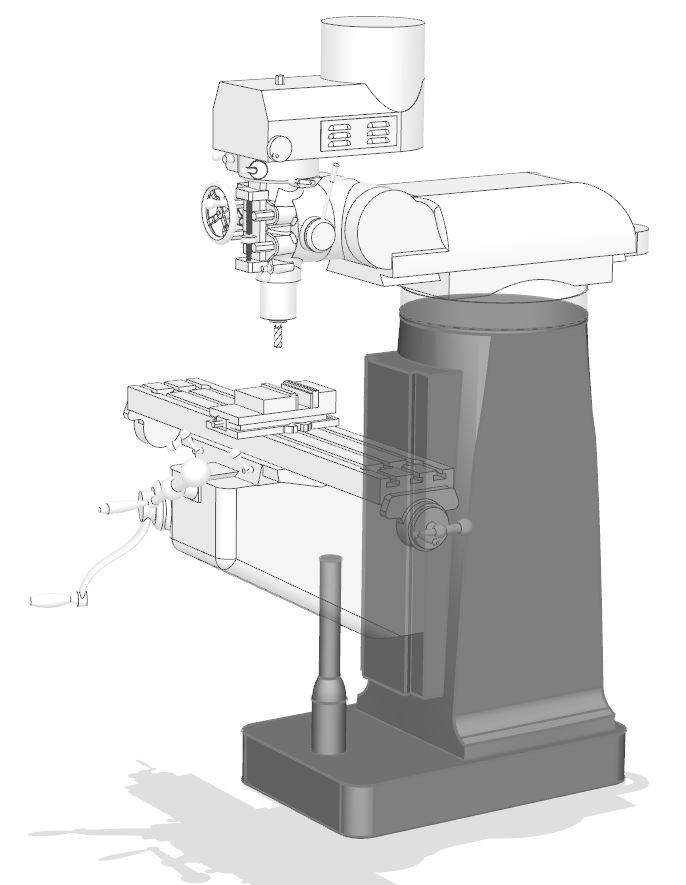

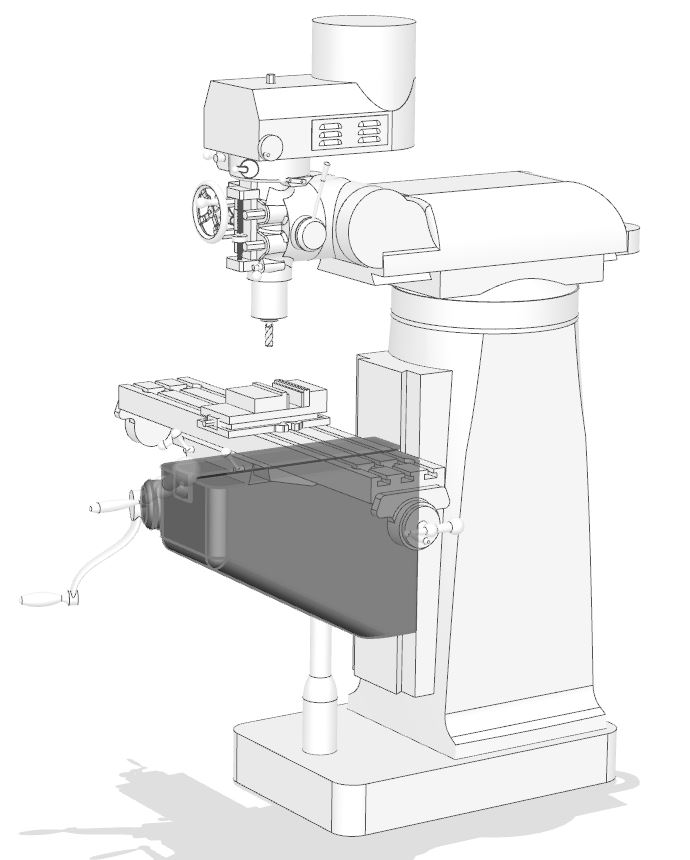

A typical manual mill is the knee mill. While these machines can vary significantly, the parts shown here are typical of most mills.

Column

The primary casting that positions the working parts of the mill is called the column. Often, the base and column are integrated into a single component. Here the base is simply a feature of the column. More…

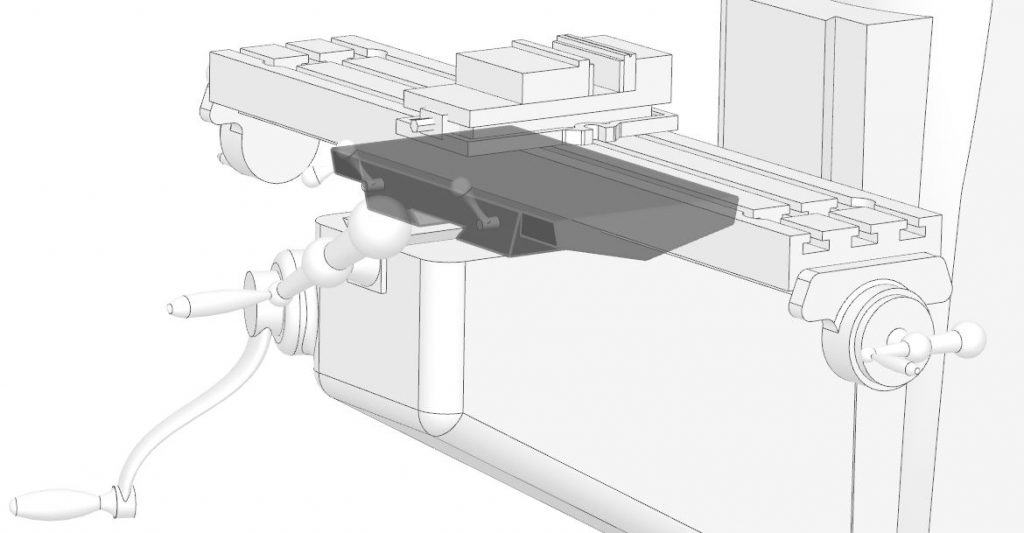

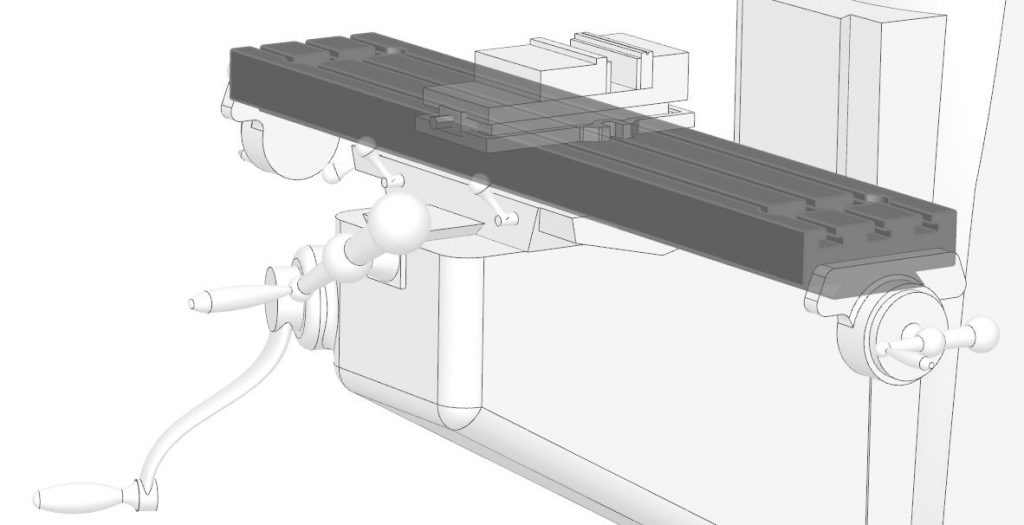

Knee

The component for which the knee mill takes its name is shown here. The knee moves vertically, and supports the saddle and table. More…

Saddle

The saddle supports the table on the knee, and provides movement left, right, in, and out from the operator’s perspective. More…

Table

On a typical knee mill, the table is able to move in three axes of motion. Work is mounted on the table by means of strap clamps, vises, chucks, or other workholding devices. More…

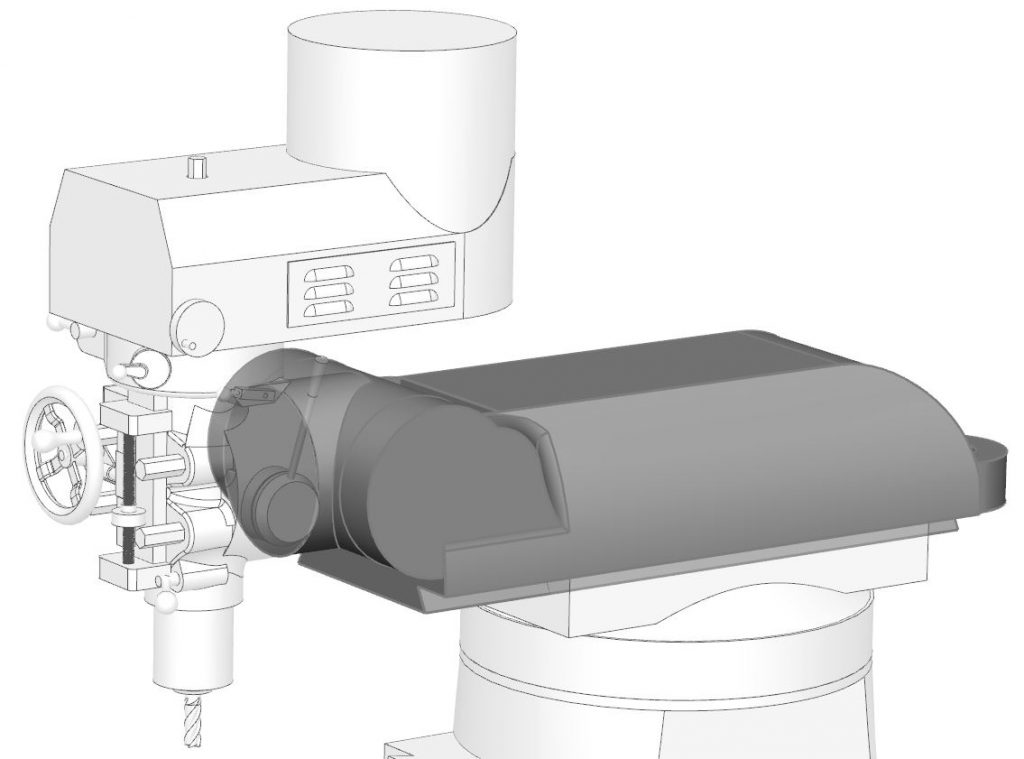

Ram

The ram allows the milling machine to be adapted to a variety of workpiece configurations and sizes. The ram is sometimes mounted to a turret as shown here. More…

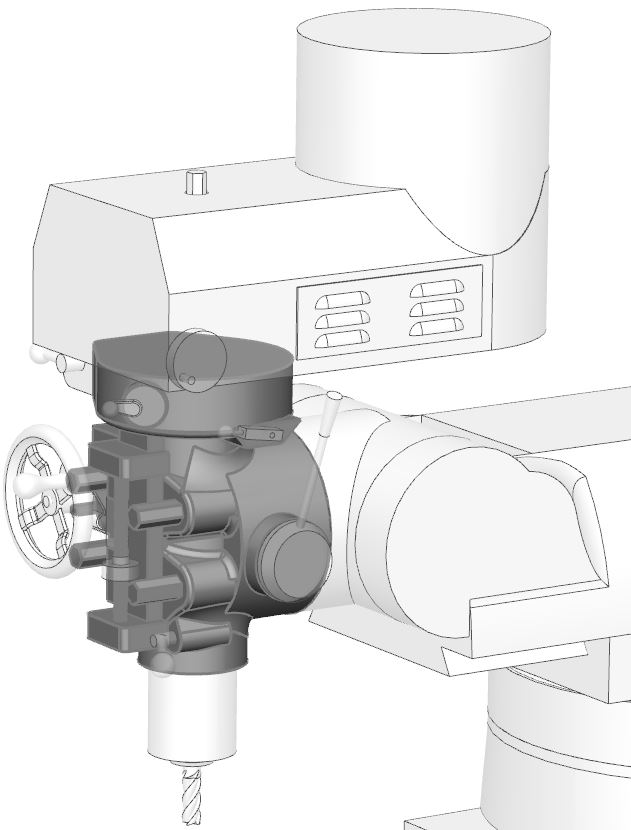

Head

The head houses the milling machine spindle and connects it to the motor. It also acts as a gearbox for the quill feed mechanism. More…

Recent Comments