- Single Point Cutting Tools

- Tool Materials

- Tool Configurations

- Monolithic Ground

- Insert

- Turning Tools

- Parting Tools

- Form Turning Tools

- Knurling

- Drilling Tools

- Tool Holders

- Tool Post Holders

- Holders for CNC Lathes

- Tool Posts & Tool Changers

- Tailstock Tooling

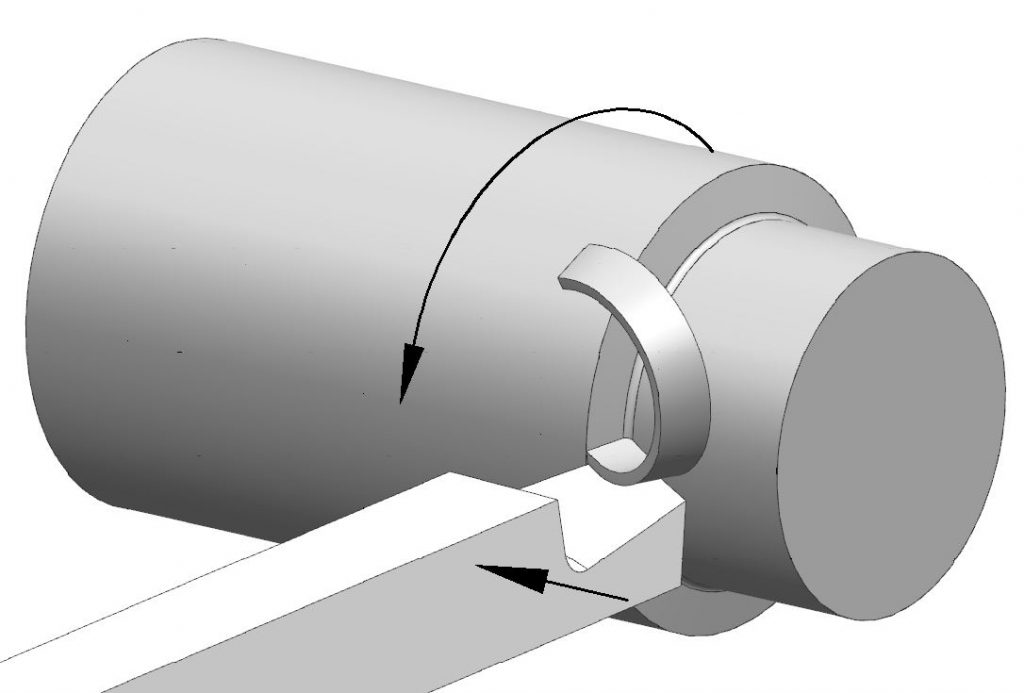

Lathes work by moving a tool into contact with a rotating workpiece. Since there is a wide variety of features that may need to be produced in a workpiece, there is a wide variety of tools that are available.

By far, the most common type of operation performed on a lathe is the removal of metal by cutting. Cutting tools on a lathe usually have a single cutting point. Multiple point tools such as drills, end mills, taps, and reamers will be discussed separately.

Single Point Cutting Tools

The most basic cutting operation on a lathe is straight turning. In straight turning a wedge-shaped tool is fed into the workpiece along its axis as shown below.

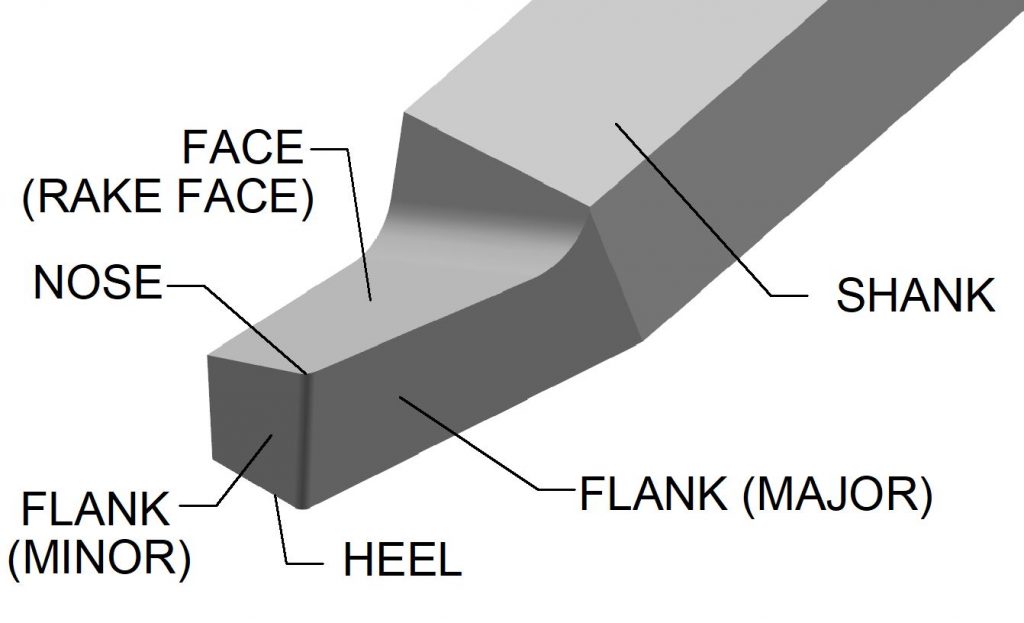

Single point cutting tools are available in a seemingly endless variety of configurations, but they tend to have many common elements. A look at a solid shank single point tool helps establish a common terminology that applies to a wide range of tools.

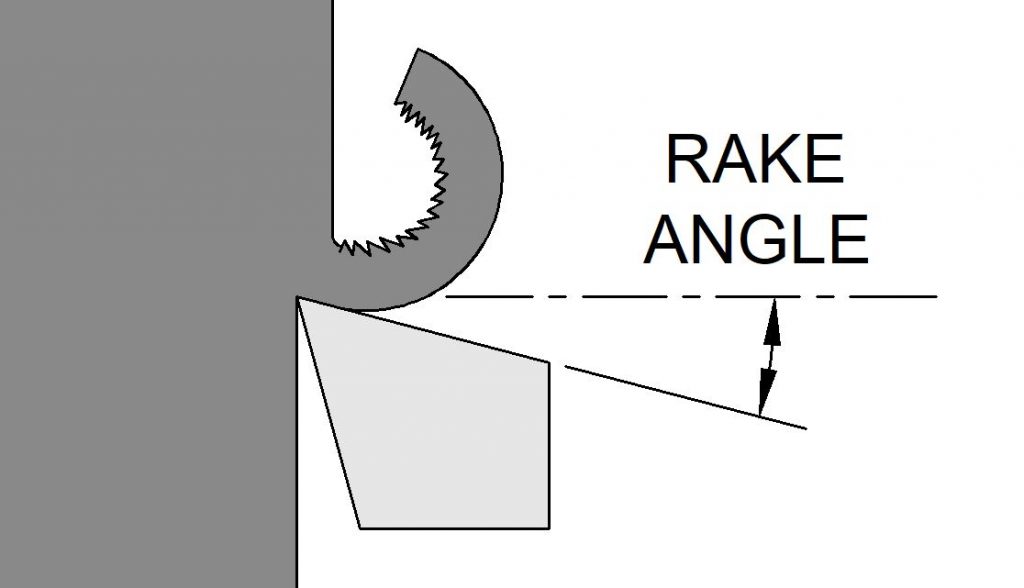

A closer inspection of the process shows some important geometry related to the cutting process. The most important types of angles are rake angles and clearance angles.

Rake Angles

As the tool engages the material, it shears off the outer surface. The angle of the cutter’s top surface (called the rake face) relative to a plane perpendicular to the machined surface is called the rake angle.

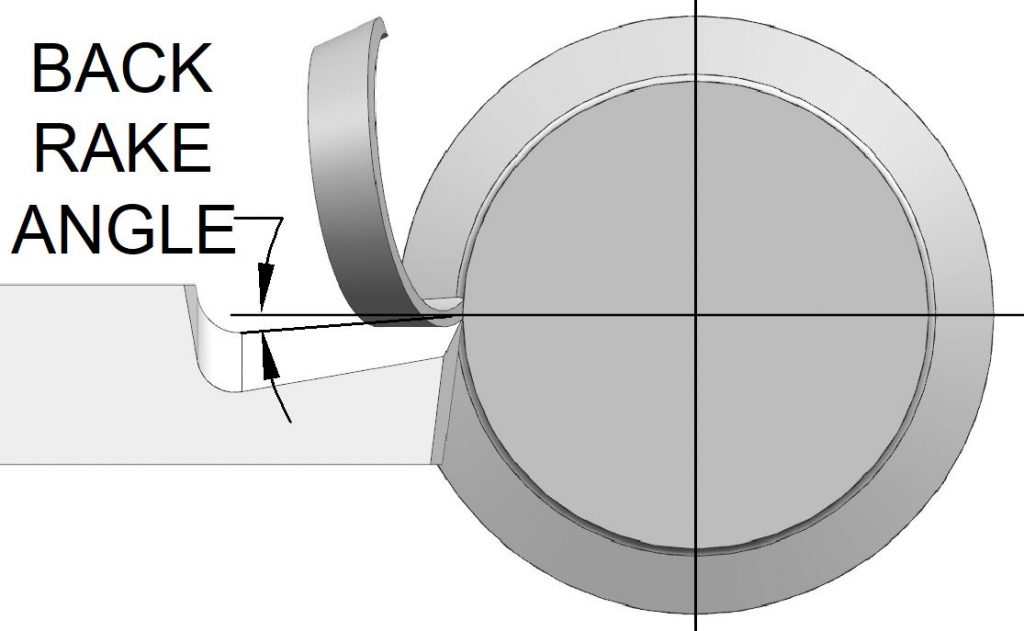

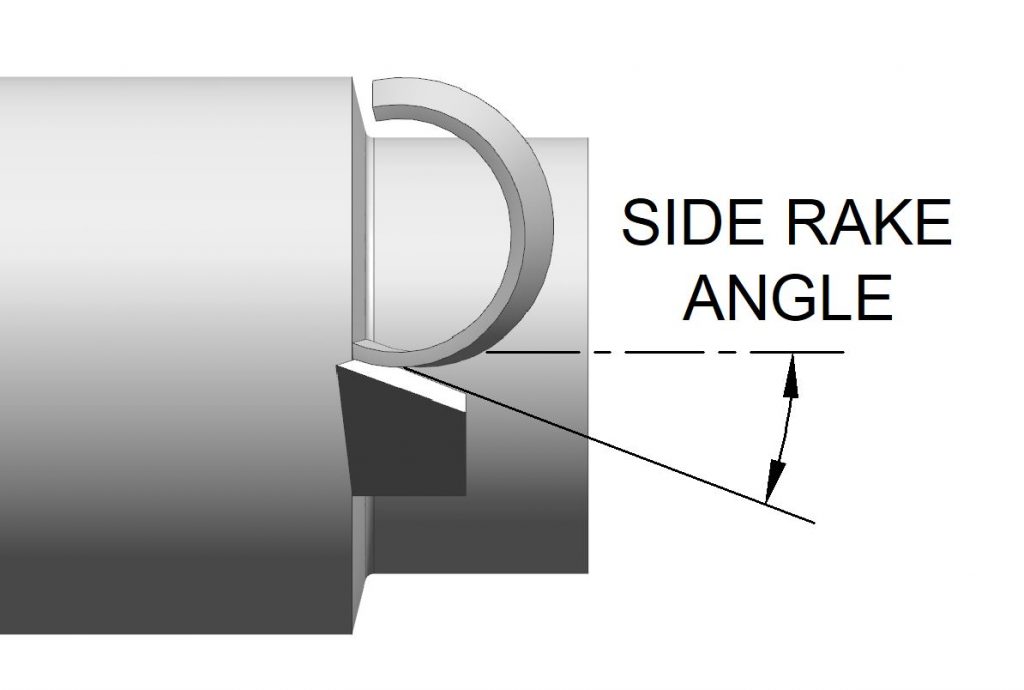

A single point cutter such as those used in the lathe often have a rake surface that makes a compound angle with the machined surface. In this case, the plane of the rake face of the tool has two distinct angles, the back rake angle and the side rake angle.

Notice you are looking at the back of the tool. The back rake angle is also known as the inclination angle.

Rake Angle & Clearance Angles – Show side view

in the types of cuts that are required to produce different features

The side rake angle when you look at the side. Effective Rake

Cutting tools can take many forms.

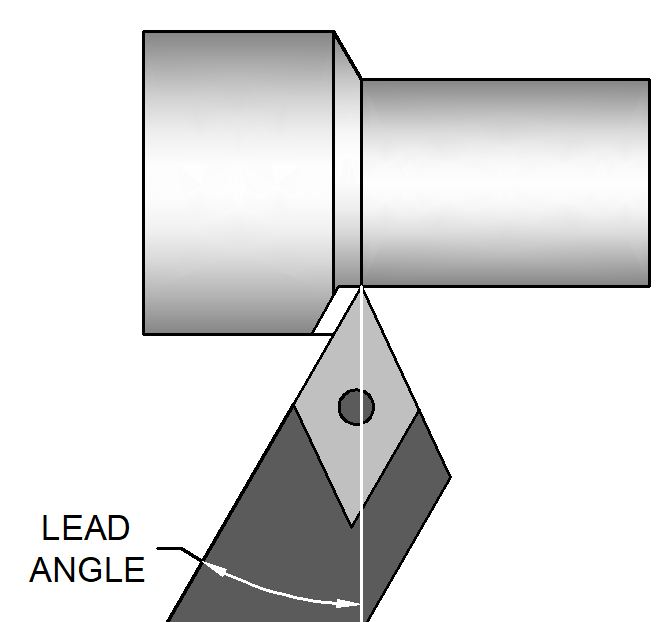

Lead Angle

The lead angle can reduce the chip thickness and improve tool life.

Tool Materials

See also: Cutting Tool Materials

Lathe tools are available in a variety of tool materials. The choice of tool material depends primarily on the material to be machined and the production rate and quantity required. The most common too materials are:

- High Speed Steel (HSS)

- Tungsten Carbide

- Cermets

- Ceramics

- Poly-crystalline diamond (PCD)

- Poly-crystalline Cubic Boron Nitride (PCBN)

Generally speaking the list above is in order of increasing hardness. The tungsten carbides are the most popular cutting tool material for industrial applications.

Cutting tools commonly are coated with a hard, abrasion resistant covering.

One way to categorize cutting tool materials is by their workpiece material groups (ISO 513). These groups allow a user to select a suitable cutter by the material it is intended to machine. Each material group is subdivided into more refined categories.

- P (blue) – Steel

- M (yellow) – Stainless Steel

- K (red) – Cast Iron

- N (green) – Non-Ferrous Materials

- S (brown) – Special, High-Temperature Alloys

- H (gray) – Hardened Materials

Tool Configurations

Depending on the specific requirements of the tool, lathe cutting tools are available in different configurations. Tools can be ground from a single piece of material (usually steel), or the tools can be compound “tipped” tools consisting of a cutting tool blank attached to a shank.

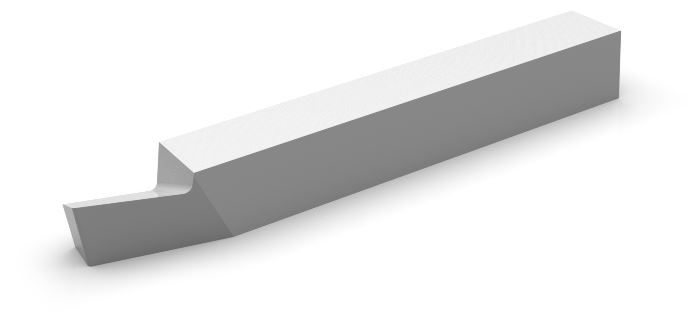

Monolithic/Ground Tooling

Tools can be ground from a solid, usually square or rectangular shaft. High speed steel is the most common tool material used in this form. This is the oldest tooling configuration, but is rarely used in industrial setting today, except for specialty applications.

Insert Tooling

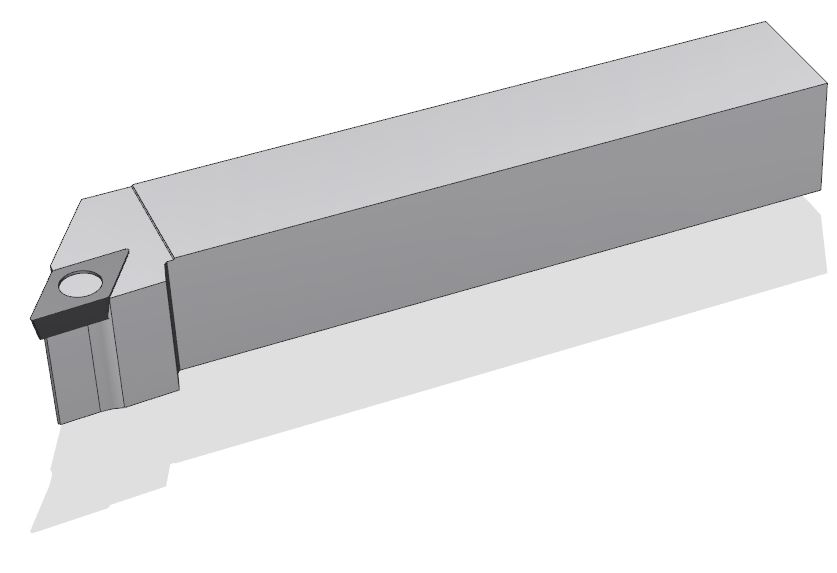

By far the most commonly used lathe tools utilize a compound structure that utilizes separate materials for the cutting edge itself and the tool shank. This compound style of tooling is sometimes called “tipped” tooling. The tip consists of a shank and an insert. Inserts are used in two different ways: either affixed to the shank by brazing, or as mechanically clamped indexable inserts.

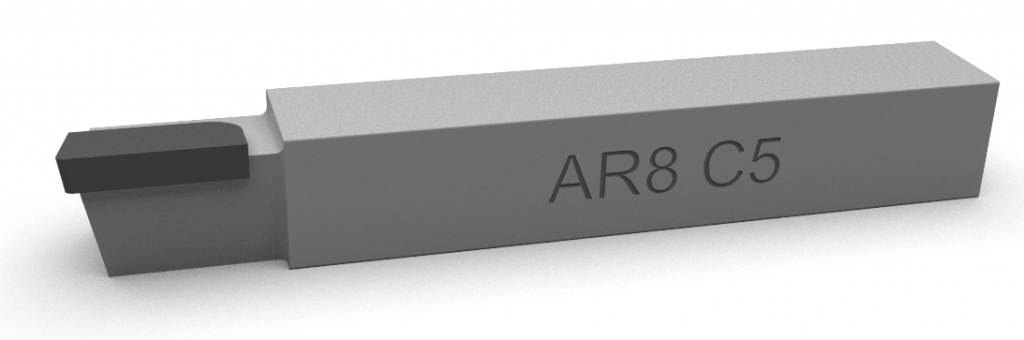

Brazed Carbide

One form of insert tooling is a brazed carbide tool. These tools have a carbide cutting blank affixed to a steel shank by brazing. Carbide tools first found use as brazed tools, and this tool configuration is popular in limited industries. Brazed carbide inserts are available in a variety of standard configurations. American National Standard ANSIB212.1-2002 specifies eight standard styles, each with a code letter (A-G) assigned. The carbide blanks that are brazed to the cutters are made to specific grade.

One advantage of brazed carbide tools is that they can be resharpened several times, however, most manufacturers opt for the highly flexible and efficient indexable insert.

ISO 242 defines dimensions of carbide tips for turning tools that are intended to be used on brazed cutters holders.

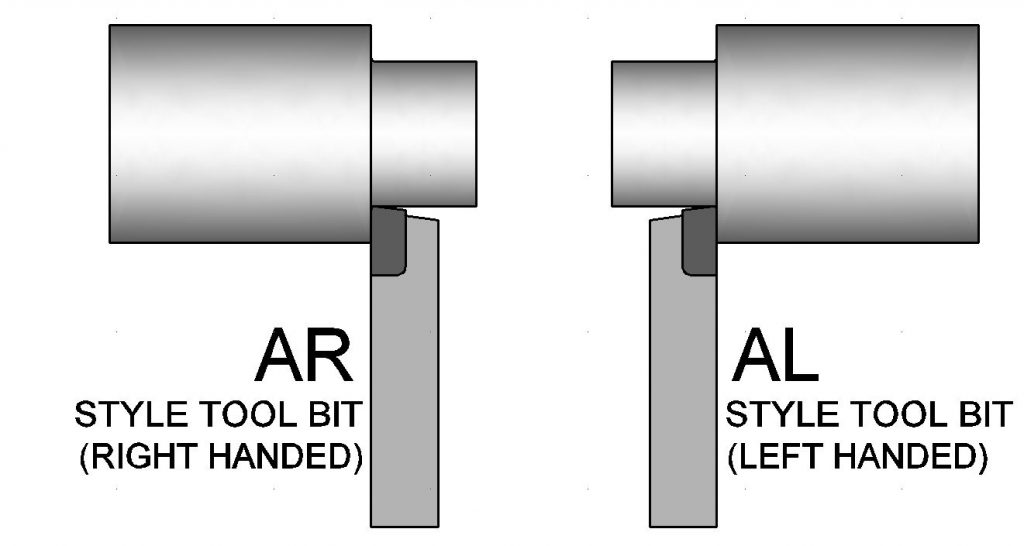

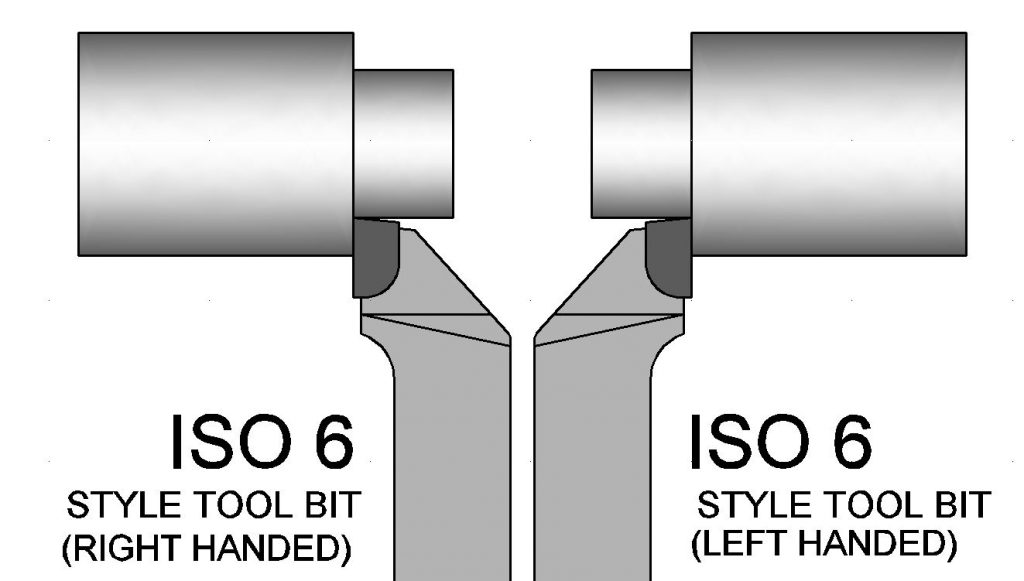

By their nature, brazed insert tools are integrated with their cutter. Brazed toolholders are available in ANSI series (ANSI B212.1) which are designated with a letter number combination (AL5 for example) or ISO standards. ISO 514 defines internal tools, and ISO 243 defines external tools. ISO tool styles are designated by a number, for example ISO 3 or ISO 4.

These have rectangular bases that can be held by the many of the same holder bases used with insert tooling.

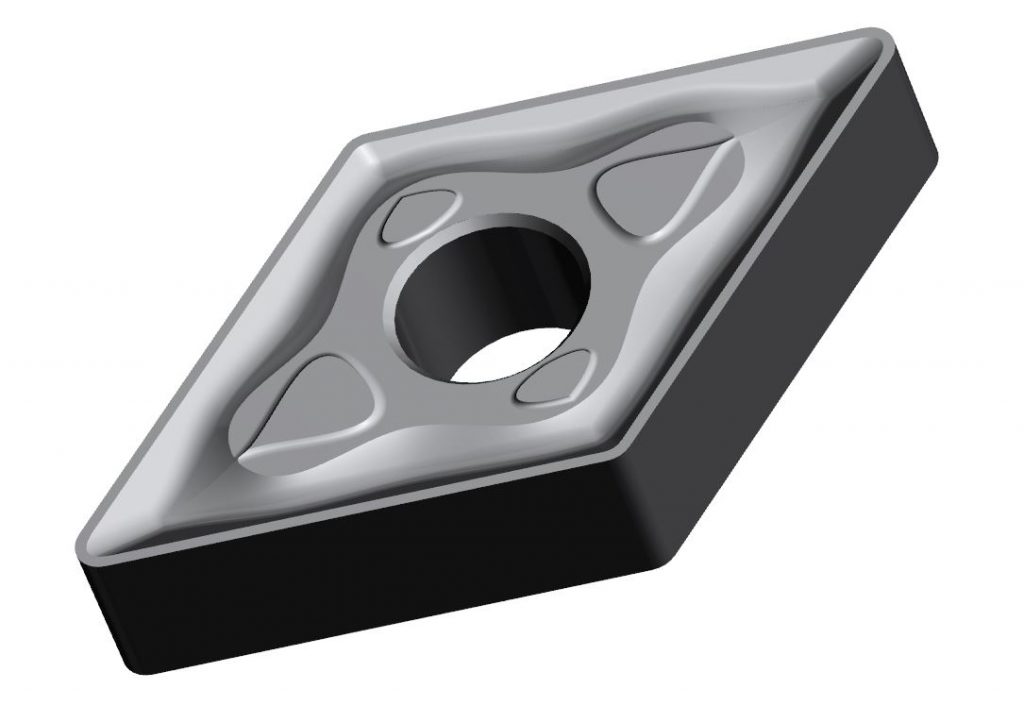

Indexable Insert

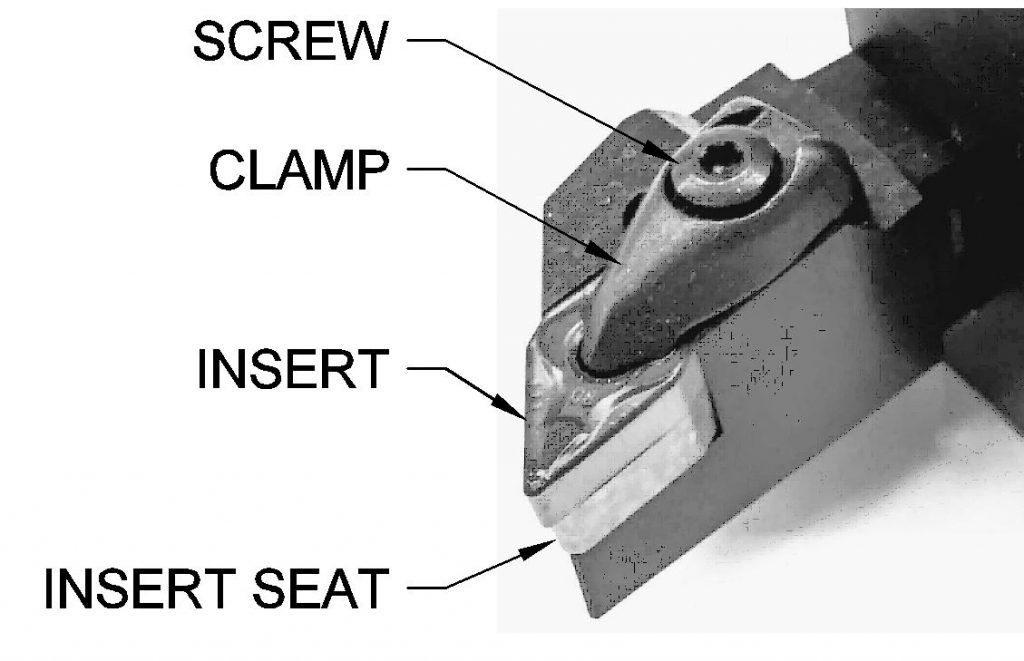

Insert tools consist of a tool holder or shank and a separate cutting component called an insert. This permits the cutting edge to be made of a different material than the tool shank. Indexable inserts are clamped to a holder mechanically so that they can be removed and either rotated to a new cutting position or replaced. It is this “indexing” feature from which this style cutter gets its name, but a few “indexable” inserts only have a single cutting configuration.

There are two standards for an identification code for indexable inserts ANSI B212.4 and ISO 1832 both define similar but unique systems that identifies an insert style by an alpha-numeric code.

Cutting Tool Coatings

- Two Methods of Application

- CVD – Chemical Vapor Deposition

- PVD – Physical Vapor Deposition

- See: Video

Tool holders

Solid Tool Holders (Shank Tool-bit Holders) were popular before the introduction of inserted tools. They were available in styles for straight, right, and left-handed cutting.

Indexable Insert Tool Holders

Tool holders are available that are designed to work with standard indexable inserts. These can take many forms to allow for a variety of rake and lead angles. ANSI B212.5 defines a system of identifying standard tool holders.

Typical Tool Holder Components

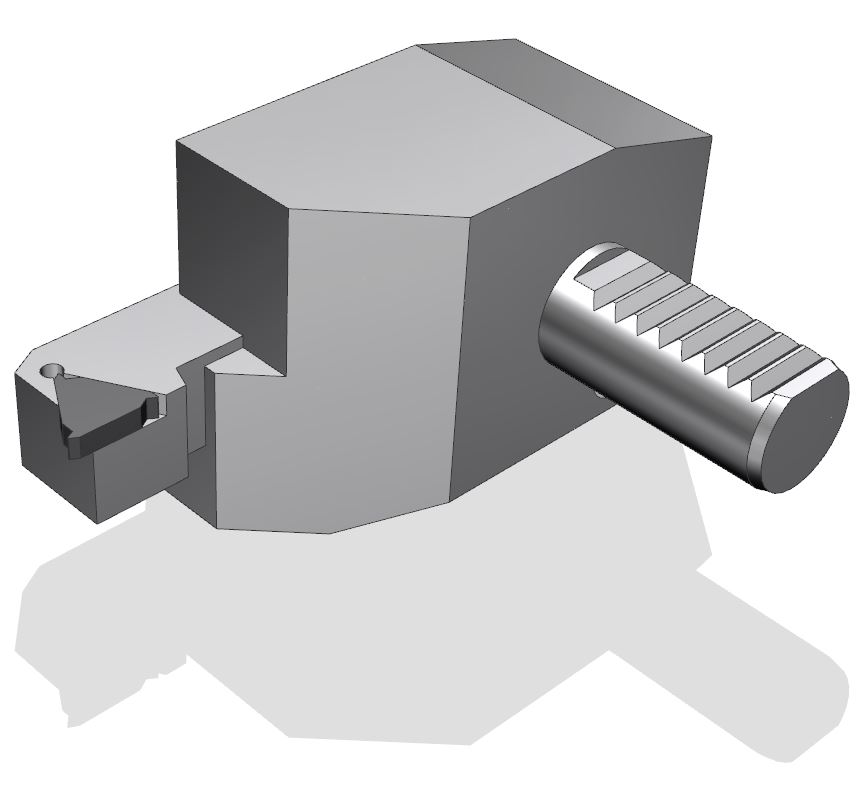

Tool Post Holders

Holders are available to adapt insert tooling to quick-change tool posts. These are normally equipped with a dovetail or other locking method. Tool post holders are designed to fit a particular style tool holder. They are available for turning and facing, boring, parting and various types of threading tools.

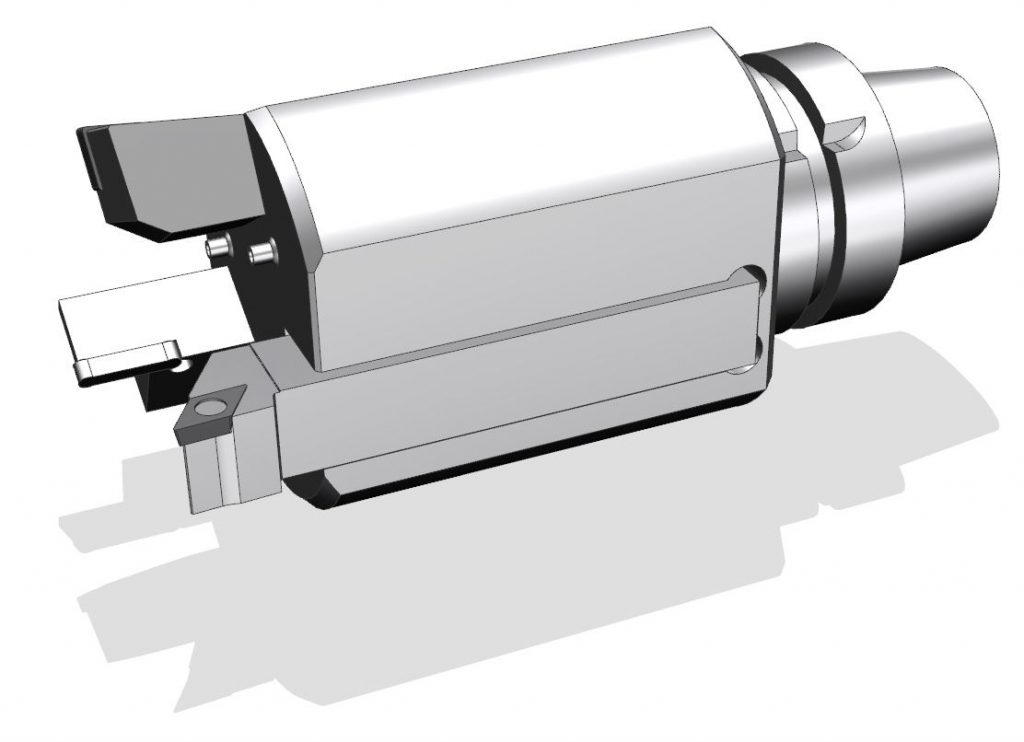

Holders for CNC Lathes

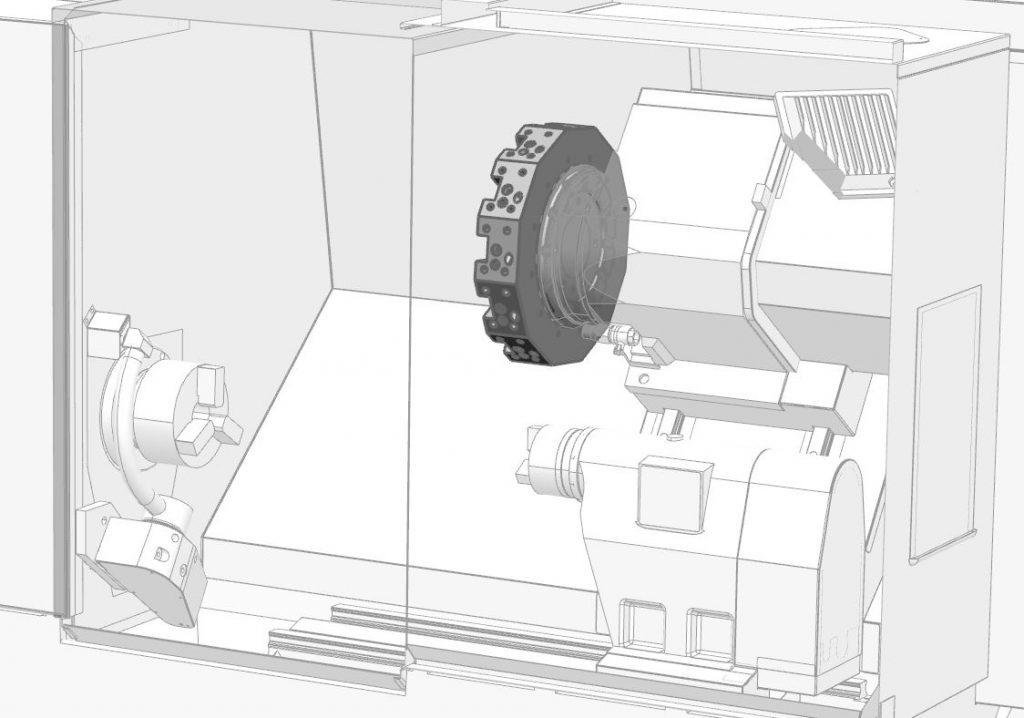

CNC lathes can have tools held by the same devices as manual machines, but it is more common for the tools to be attached to one of the following: a turret, a gang style tool changer, or a tapered spindle.

Bolt-on Turret BOT Holders

Holders for Haas style BOT (bolt-on turret) are available in a variety of styles for holding square and round shank tools.

BMT (Base Mounted Turret)

HSK – Hollow shank tapered holder for high speed applications.

VDI Tool Holders ( Verein Deutscher Ingenieure) are a German standard holder type designed to be used in a turret (see below). They are attached by means of as serrated shaft.

Bushings for holding

- Boring Bars

- Morse Tapers

- Collets

- Reducer Bushings

Live Tooling Spindles

- See BMT Turret

Tool Posts & Tool Changers

Manual Tool Posts

Most are designed to mount one of two ways:

- T-Slot with a T-nut (America)

- Bolt Shaft mount (European)

Lantern Style or Rocker Style

Manual Turret Style

Quick Change Tool post

Quick-change tool posts are available in different sizes for different size lathes. One example designation is this series:

- AXA (swing up to 10″)

- BXA (12-15″)

- CXA (13-18″)

- CA (14-20″)

- DA (17-48″)

- EA (25″+)

Automated Tool Changers

Turret Tool Changers

Turret style tool changer are very popular on CNC equipment. Turrets combine the functions of storing (tool magazines) and changing tools (tool changers).

Gang Style Tool Changers

- Can be retrofit onto QC Toolpost (see Dorian QC Gang tool)

Other Automated Tool Changers

Mill turn centers have tapered spindles like those found in milling machines and have similar toolchangers an magazines, such as chain and carousel types.

Tailstock Tooling

Tailstock spindles can also be used to hold tooling on a lathe. Examples of tooling commonly used in tailstock spindles drill chucks and tapered drill bits and reamers. Sometimes sensitive drilling attachments are used for small hole drilling. Tailstock turrets are available to index multiple tailstock tools.

References

Machinery’s Handbook, 27th ed.

https://www.doriantool.com/wp-content/uploads/SEC-B-TOOL-POST-TOOLHOLDERS-2016.pdf

https://www.haascnc.com/machines/lathes/st/models/standard/st-25.html

https://toolsmach.com/en/content/35-brazed-turning-tools

https://www.surpluscuttingtools.com/product/brazed-carbide-tipped-tool-bits

Recent Comments