Introduction

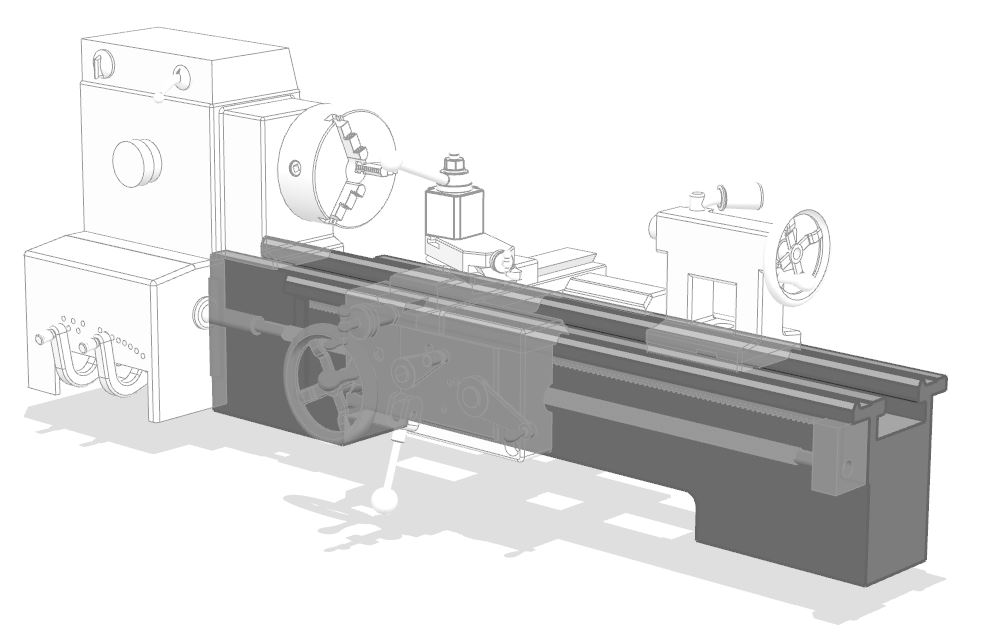

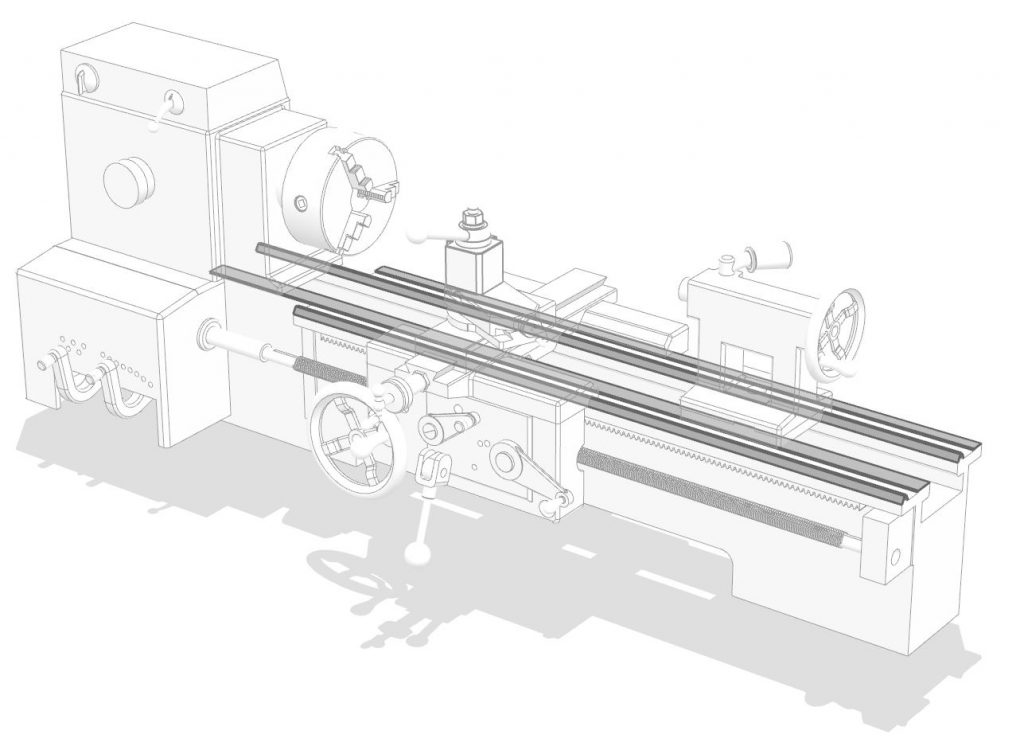

The bed of the lathe is the major structural element of the lathe. The bed provides a foundation for the ways, which in turn carry the carriage, tailstock, and other components such as steady rests and carriage stops.

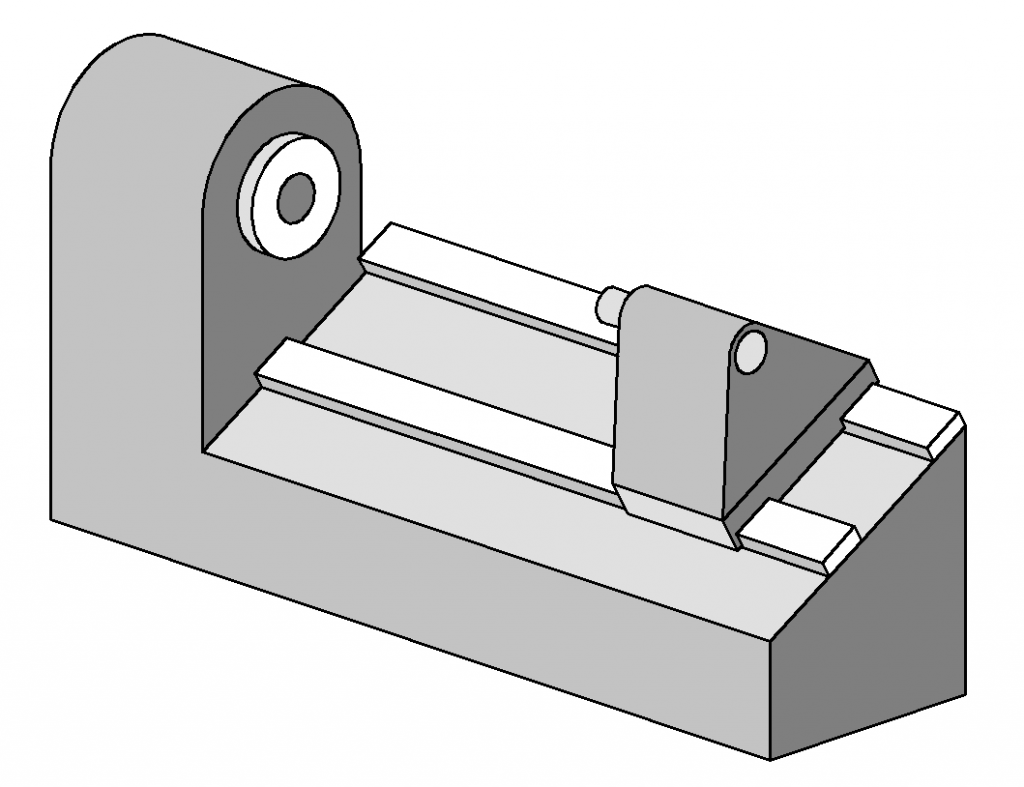

Bedways

Bedways or simply ways are linear bearing elements that provide a path of motion for the carriage and tailstock of the lathe. Bedways can have several configurations including box ways, v-ways, dovetail ways and may be used with ball or roller bearings on some lathes.

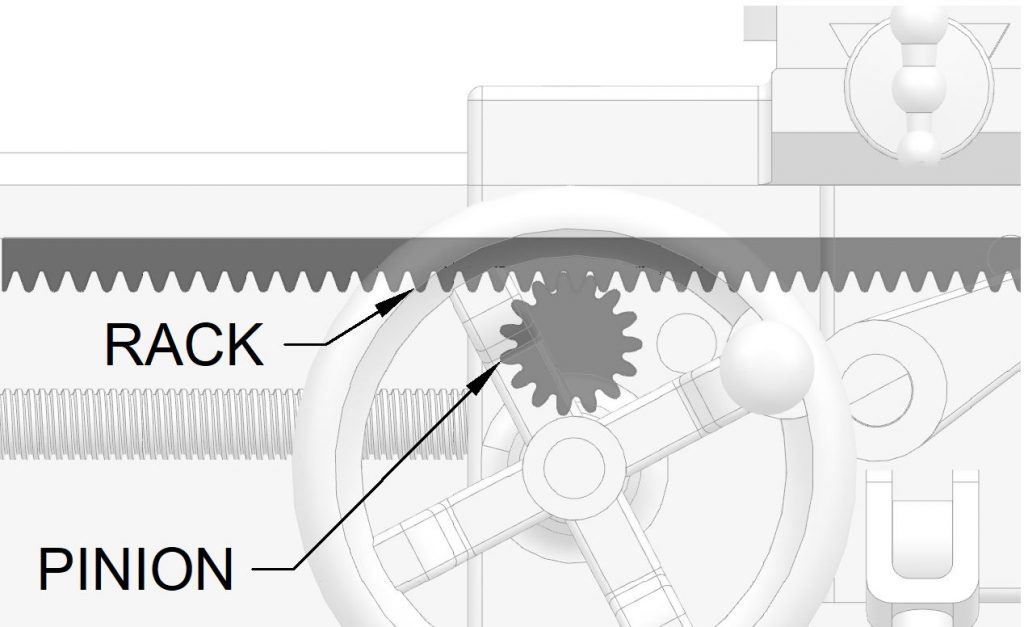

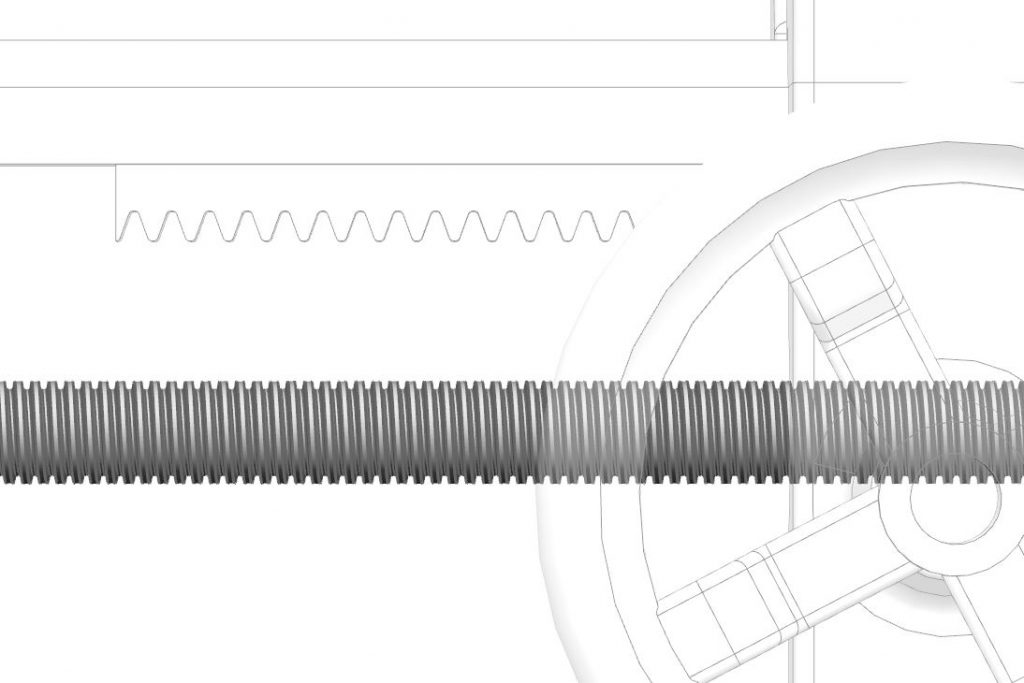

Rack

The rack is a flat, gear-toothed element that is used in conjunction with a pinion gear to provide motion to the carriage for turning operations. Power is provided to the pinion gear via the feed rod. On CNC lathes power may be supplied directly to the pinion gear via a servo motor.

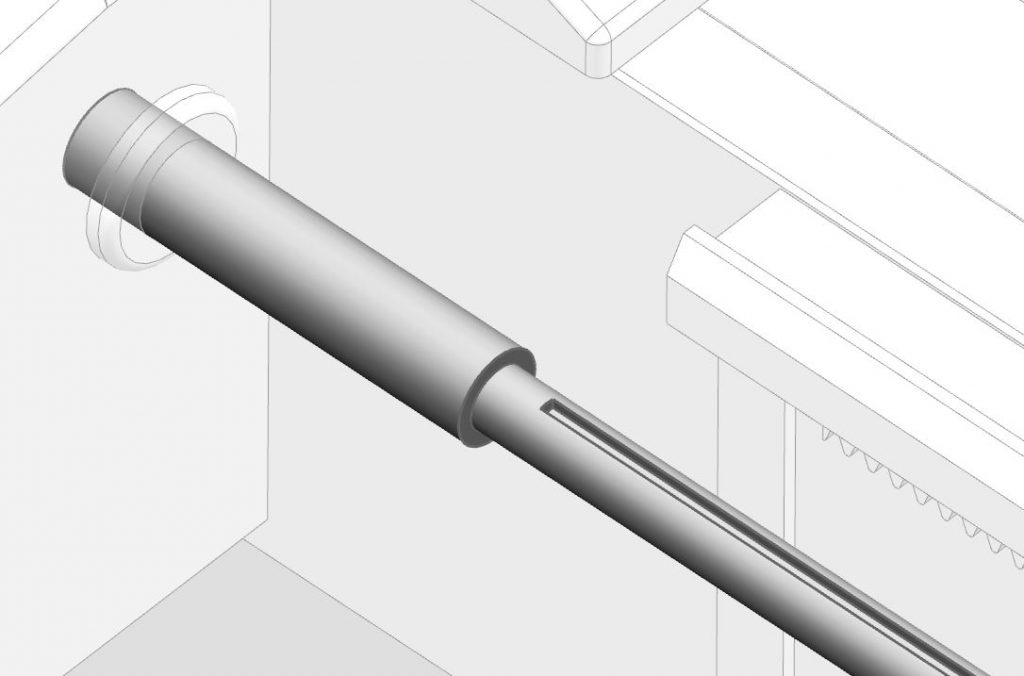

Feed Rod

The feed rod is a cylindrical rod with a keyway machined into it. A worm gear slides on this rod and transmits power either to the carriage pinion gear or the the cross slide gear depending on the position of the power feed select lever.

Note: On some lathes the feed rod and leadscrew are integrated into the same component.

Leadscrew

The lead screw is a threaded rod that is used to provide power to the carriage for threading operations. The lead screw is often threaded with and ACME thread. The lead screw transmits power to the carriage when the half nut lever is engaged.

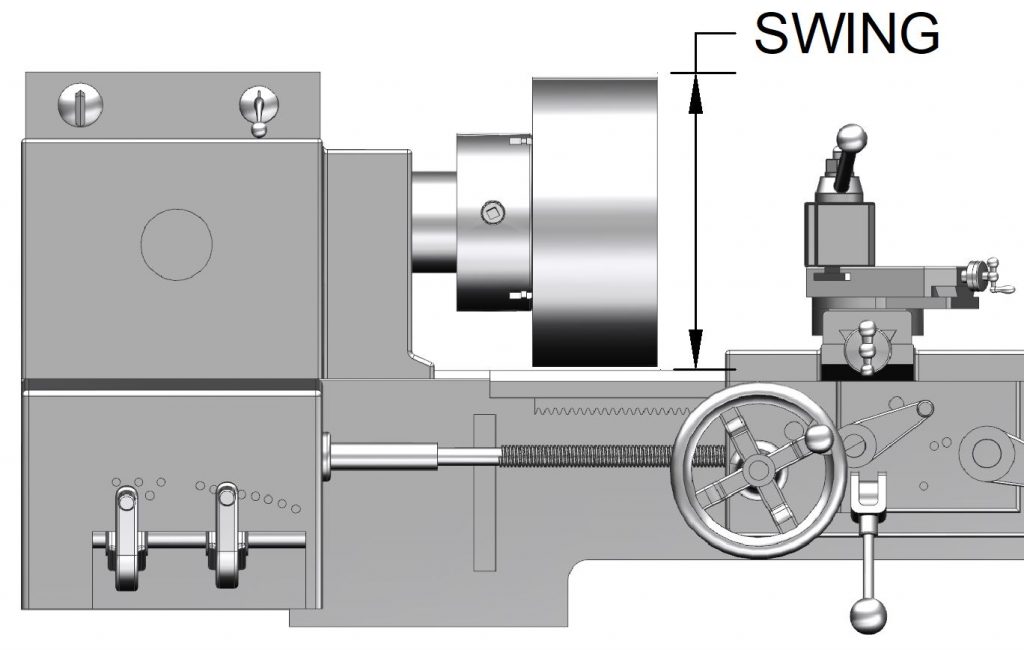

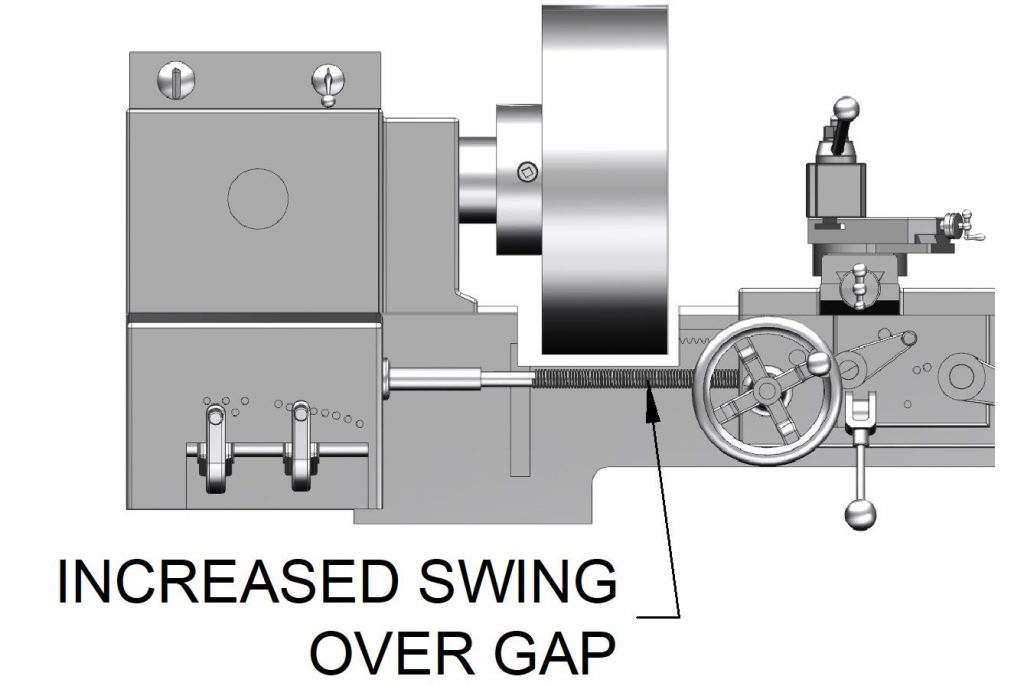

Gab bed lathes

The maximum diameter workpiece that can be turned on a lathe defines the swing of the lathe. Some lathes include a feature to increase the swing of the lathes. A (usually) removable segment of the bed known as the gap can taken out to accommodate an unusually large workpiece. When sizing a lathe, be sure to know whether the swing size is the swing over the bed, over the gap, or over the cross-slide.

Sliding gap bed (video example)

Slant Bed lathes

Slant bed lathes feature a tilted bed arrangement. The angled orientation allows chips to fall out of the way. This arrangement can also increase the spacing between the ways to provide more stability.

References

Rogers, Barry. “Buying a Lathe: Slant-Beds and Multitasking Configurations.” Modern Machine Shop. August 17, 2018. Accessed May 17, 2019. https://www.mmsonline.com/blog/post/buying-a-lathe-slant-beds-and-multitasking-configurations.

Recent Comments