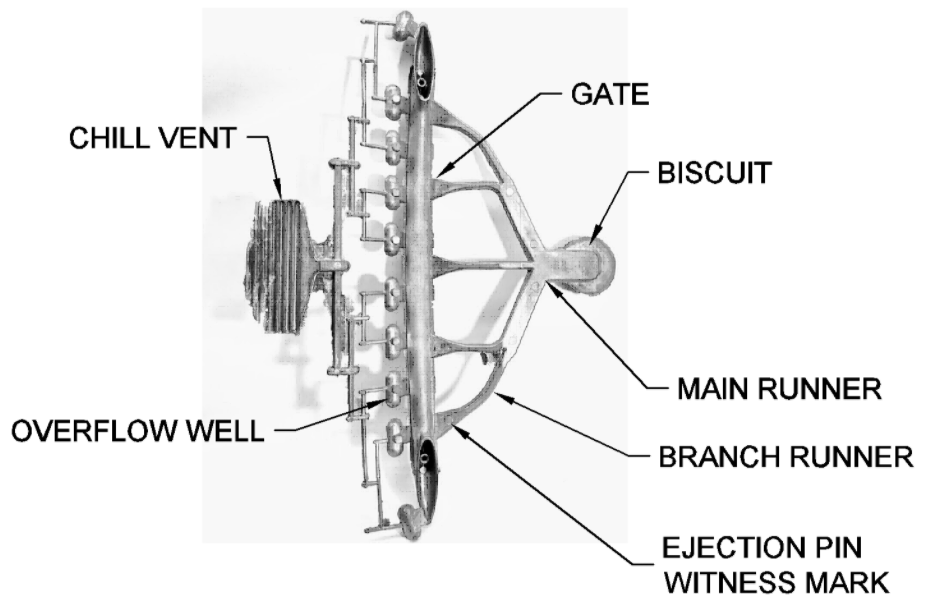

Die Casting (Pressure Die Casting)

- Sometimes called “Pressure Die Casting”

- Molds are used multiple times

- Metal is forced into die under pressure

- Better for high production

- Molds are usually made of metal

- Complex shapes are possible

- Castings have to have a relatively low melting temperature

- Zinc

- Aluminum

- Magnesium

- Design Considerations

- Design with draft angles

- Avoid Undercuts

- Avoid Cores

- Holes can be problematic

- Round corners

- Fillets

- Rounds

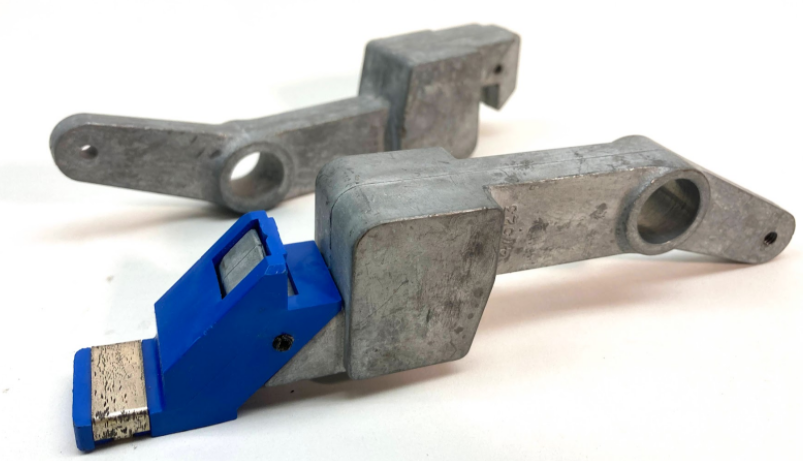

Typical Die Cast Parts

Die casting may require finish machining after casting

Recent Comments