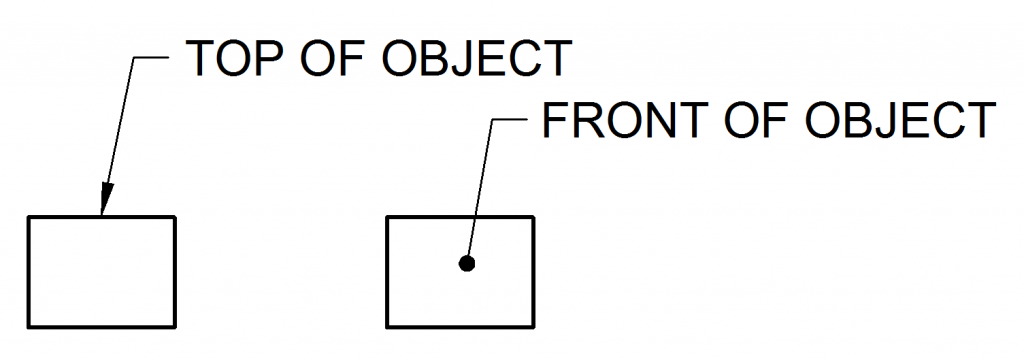

Leaders are used to indicate information about hole diameters, radii, and other information that occurs as a specific location or on a particular surface on the drawing. Leaders are drawn as straight lines, but they must be drawn at an angle other than horizontal or vertical. They should have a level “elbow” at the end where the note is located. Leaders with arrowheads must terminate on an object line. Leaders should not be unnecessarily long, and they should not cross each other. They should be drawn at an angle that is different from the surrounding object lines. The angle between the elbow and the leader line must be large enough to be obvious. Leaders can be ended with a round dot (approximately 1.5mm in diameter) if they are intended to indicate an area on a surface.

Recent Comments