- Surface Plates & Granite Shapes

- Reference Masters

- Height Masters

- Bench Centers

Surface Plates

Surface plates are a fundamental measuring tool. They provide a nearly perfect plane on which other measurements can be made. Surface plates are available in a variety of tolerance classes:

- Grade AA is the most precise, used in laboratories

- Grade A is for general inspection work

- Grade B is for shop floor work

See: ASME B89.3.7-2013 (the older standard was Federal Specification GGG-P-463c)

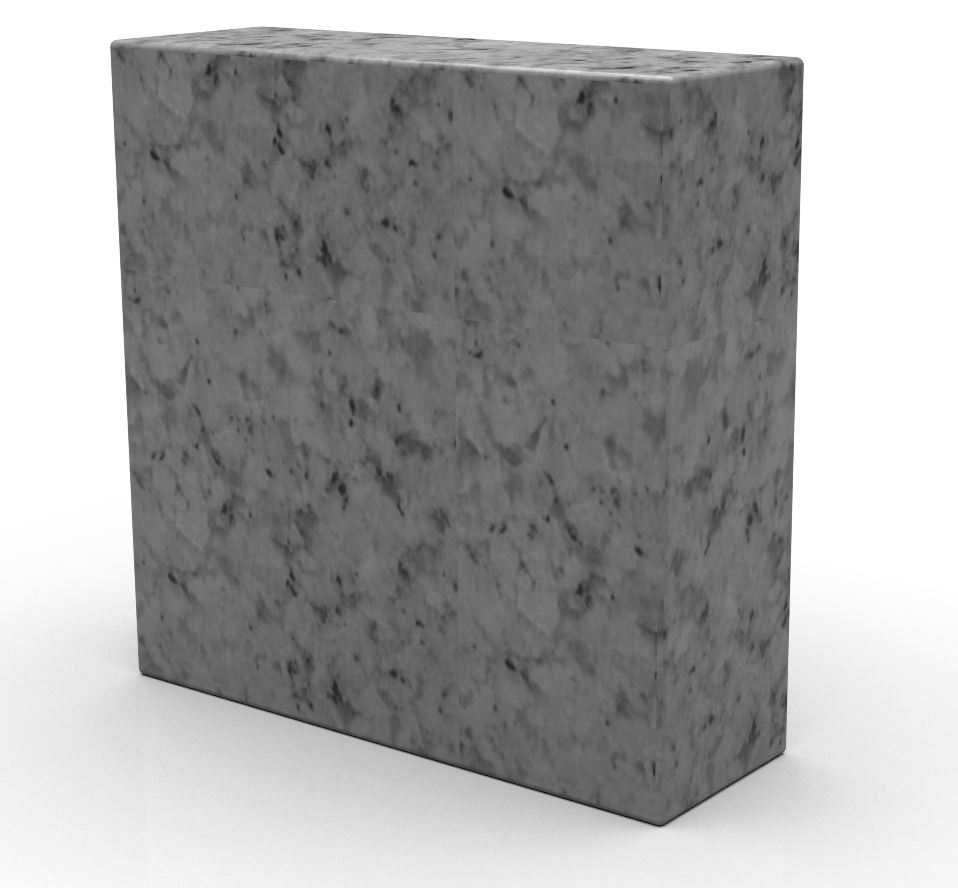

Granite Master Squares

Used for checking squareness of machine tools.

Granite Parallels

Useful for creating inspection datums. Often used when a part has protrusions on an otherwise flat surface.

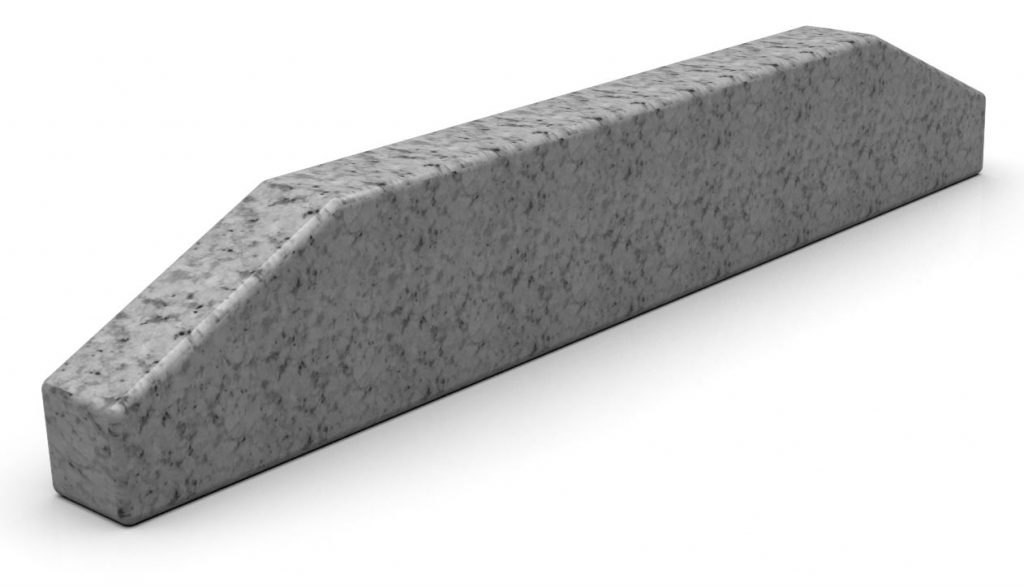

Granite Straight Edges

Used to compare flatness and straightness of long parts such as machine bedways.

Granite V-Blocks

Granite Six-Face Cubes

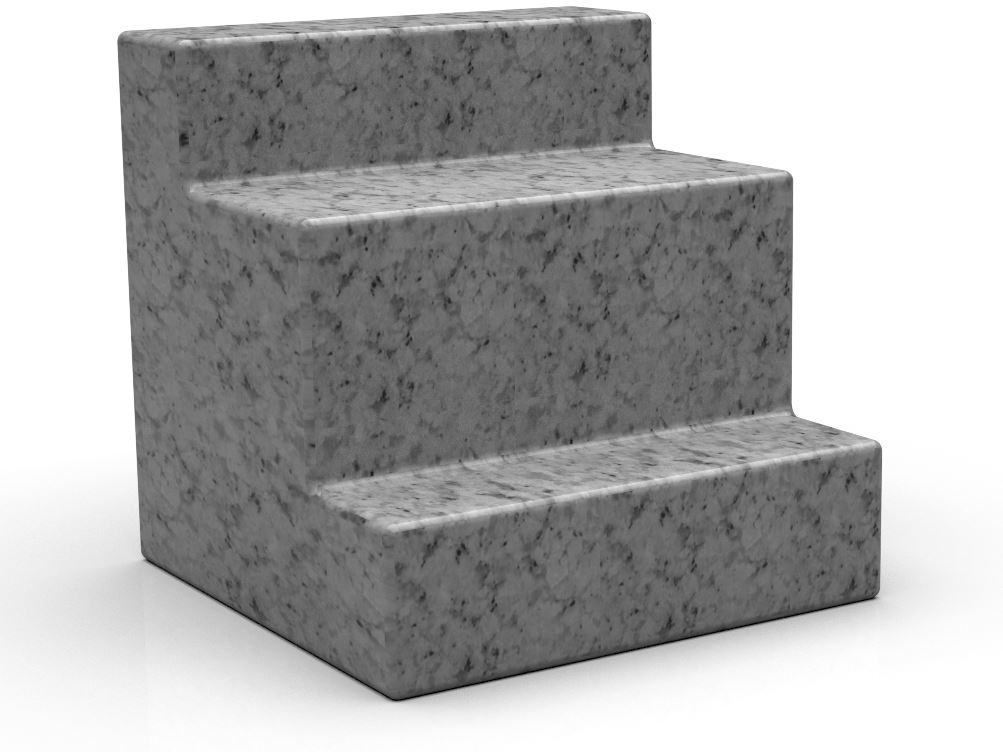

Granite Angle Plates

Granite angle plates can provide a perpendicular surface to the plane of a surface plate.

Gage Blocks

Gage blocks are made with extraordinary precision to very tight tolerances. They can be combined to produce a wide range of sizes.

Gage blocks are made to standard grades:

- 00 – Most exact tolerance

- 0 – Suitable for inspection

- AS -1 – Between shop floor use and inspection

- AS-2 – General shop use

See ANSI/ASME B89.1.9M (and the older U.S. Federal Specification GGG-G-15C). Former grades were AAA, AA, A, and B and .5, 1, 2, 3.

Gage blocks must be wrung together to produce accurate results.

Plug & Pin Gages

Gage Balls

Ring Gages

Height Masters

Height masters are used to calibrate height gages.

Bench Center

Recent Comments